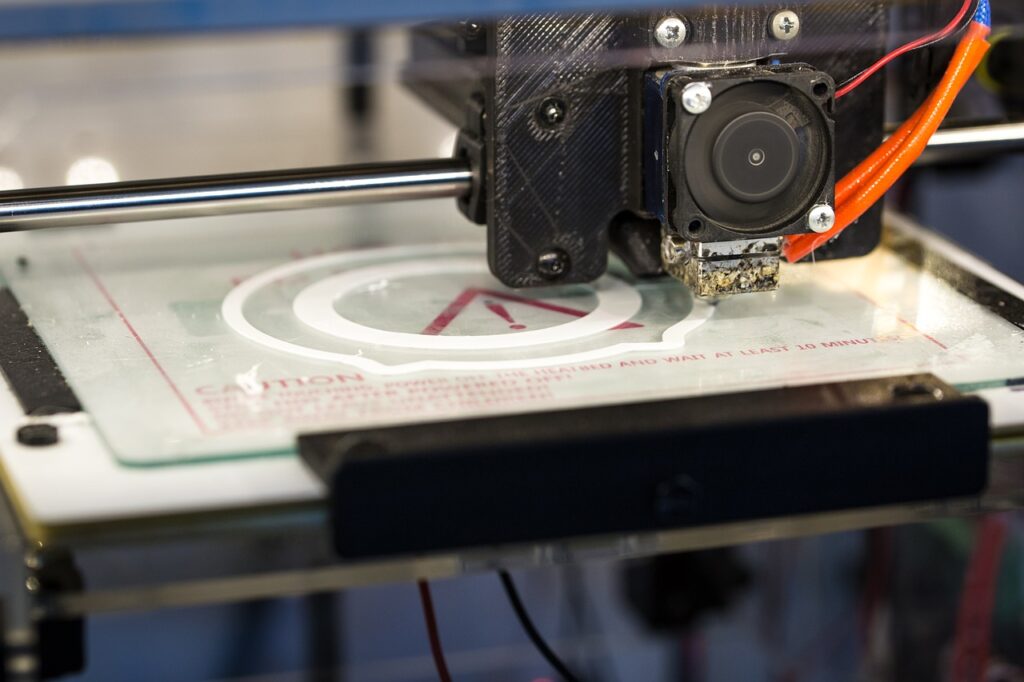

There is constant evolution in 3D printer filaments with the frequent addition of new colors and materials to the ever-expanding range. Filaments are plastic materials similar to spaghetti strands and come in rolls, making them easy to load into your 3D printer. They are melted and extruded onbed to create your 3D model according to the specifications you have chosen in your 3D software.

3D Filament types

The type of 3D filament you choose can often determine the quality and success of your print. Every 3D printer has criteria to put into consideration when choosing a filament.

These criteria include chemical resistance, thermal resistance, mechanical resistance, flexibility, and ease of use for successful print results. In this article, you will learn about 3D filaments and their available types.

PLA

PLA (which means polylactic acid) is the most widely used filament for 3D printers. PLA is a reasonably cost-effective thermoplastic made from renewable sources and is suitable for most prints that do not require mechanical strength.

PLA is an easy-to-use filament that you can print at reasonably low temperatures. This prevents its adhesion difficulties and warping. Also, it is a material that does not emit toxic fumes when printed. It can seep and ooze, but if it does, it can be minimized by optimizing the 3D-cutter settings.

PROS

- Easy to print and inexpensive

- Sustainable

- Glossy

- Odorless

- It does not require heating

- Wide color gamut

- Ease of post-processing (sanding, painting, etc.)

- Cost-effective

- Good shelf life

- Strong and durable

- Dimensional accuracy

CONS

- Low-temperature resistance

- Rigid

- Moisture sensitivity

- Not suitable for extended outdoor use

- The filament may become brittle and break

- ABS

ABS means Acrylonitrile Butadiene Styrene. It is a thermoplastic material commonly used in 3D printing due to its flexibility, durability, strength, and excellent properties. Due to ABS properties, ABS bends and deforms before breaking, and it is suitable for printing screws, gears, or mechanical systems subject to external forces.

ABS is a polymer often used in the injection molding industry, so it naturally shrinks more than other polymers. In 3D printing, shrinkage can cause difficulty in adhesion and bed deformation.

Its high hardness makes it suitable for use in the automotive industry, household appliances, or stamping, where durability is essential. Unlike PLA, ABS is not biodegradable, and it is not generated from renewable sources.

PROS

- Strong and durable material

- Good impact and abrasion resistance

- Good thermal resistance

- Resistant to most environmental conditions

- Simple post-processing (painting, sanding, etc.)

- Cost effective

- Fewer fasteners for more smooth surface

CONS

- Non-biodegradable

- Parts tend to shrink, causing dimensional inaccuracies

- Requires heated bed or chamber

- High risk of warping (requires strong adhesion)

- Create pungent odor and VOCs during printing

- PETG

PET means polyethylene terephthalate glycol. It is a filament made of thermoplastic polyester used in making bottles, containers, and many of our everyday products. It is a perfect alternative for PLA and ABS due to its high strength, temperature, and water resistance.

PETG (polyethylene terephthalate glycol) is well known for its flexibility, transparency, easy usage, and perfection for beginners. Ingredients may vary for different products.

PROS

- Ease of printing

- High chemical resistance

- BPA free: Low shrinkage

- Low moisture absorption

- Odorless

- Good adhesion with low durability

- No coating required

- Glossy finish

CONS

- Fine adjustment required

- Possible stringing

- Low flexibility, rigid material

- Poor jumper properties

- Can be connected

- Nylon

Nylon Printing Filament is a solid and durable 3D printing filament. This filament is commonly used for making functional parts because it is resistant to wear and tear and has a high melting point. This high melting point makes it an excellent choice for crafting 3D-printed tools and locking gears. Even though the nylon filament is durable, it tends to be hygroscopic, which means its performance can be unpredictable from time to time.

PROS

- Extremely strong and flexible

- Good abrasion resistance

- High impact resistance

- No odor during printing

- Withstands adverse weather conditions

- Good dimensional stability

- Excellent mechanical resistance and impact resistance

CONS

- Vulnerability to warping

- The poorly dried filament can cause print defects

- Sealed storage is required to prevent water seepage

- Not suitable for wet environments

- Flex

Flex is a filament made of a combination of plastic and rubber. The main advantage of Flex filament is that it produces flexible prints with elastic properties. Its flexibility allows the material to stretch and bend easily.

You can use Flex for rubber wheels, mechanical grips, or solid and durable components with exceptional shock absorption at 100% infill.

The elasticity degree of the plastic depends on the type of TPE and the chemical formula used by the manufacturer. For example, some filaments may be partially flexible, like a car tire, but others may be elastic and completely flexible, such as rubber bands.

PROS

- Flexibility and softness

- Excellent vibration reduction

- Good shock resistance

- Long service life

CONS

- Printing difficulty

- Poor bridge

- May have stains and wires

- It may not perform well in a Bowden extruder

Conclusion

You can create various products with a 3D printer and can mostly be limited by your imagination. There are several types of filaments with various properties and purposes for the creation of these 3D artworks. When choosing Your 3D printing filaments, consider the listed properties, advantages, and disadvantages above. We hope you enjoyed learning more about some of the 3D filaments.