3D printing has come along by leaps and bounds. Modern 3D printers, like my Creality K1 Max, have far fewer problems than the printers I first used more than a decade ago. Yet, there are still a long list of issues that can crop up that feel maddening to resolve, and these are five of my personally most-hated ones.

Heat Creep

A 3D printer has a hot end and a cold end, and when it’s working the way it’s meant to, things that should be hot are hot and other things are not. When heat creep happens, heat from the hot end makes it to parts of the printer it should not, and the filament can get soft before it’s supposed to.

In my printer, there’s a small teflon pipe that goes from the extruder to the heat brake, and after a long print the filament in that pipe gets soft, expands, and then gets stuck in the pipe. The only way to fix this is to open up the printhead assembly and remove that pipe. Then heat it up with hot water and get the filament out.

I’ve tried preventing this by lowering the temperature but still remaining in the rated temperature for the filament, and it’s not a common issue, but I have noticed it happens more with specific filaments, so it’s not necessarily an issue with your printer. Some filaments might be more heat sensitive and suffer from creep because of it. If it happens no matter what, you may have to investigate your hot-end or recalibrate it.

Invisible Nozzle Blockages

The nozzle on most 3D printers has a tiny hole, and unless the nozzle is clear it doesn’t take much to partially or sometimes totally block it. You can tell when running an extrusion test if the filament starts bunching up to one side of the nozzle for no apparent reason.

Other than putting in a whole new nozzle (which is usually cheap and easy), the only way to really sort this out is to use nozzle cleaning needles and, in some cases, to perform the cold pull method where you use molten filament and some finesse to remove residue from the nozzle. Personally, I’ve used a combination of cleaning needles and the metal plunger that came with my printer to get some of that burnt debris out, but sometimes five minutes and a $2 replacement nozzle is the shortest route to sanity.

Crazy Abrasive Filaments

One of the things I was most excited about when re-starting my 3D printing journey a few months ago was printing with glow-in-the-dark filament, which we did with gusto. Except, it turns out these filaments contain small shards of metal or glass (depending on the composition) that eat through brass nozzles like a toddler who found a tub of cookie dough.

Usually I can go through ten or more rolls of filament before my brass nozzle’s wear becomes an issue, but a single roll of glow-in-the-dark is enough to ruin a nozzle. The real answer is to get a hardened steel nozzle, but I’ve been having a devil of a time sourcing one where I live. That’s probably not an issue for you, but the bottom line is if you’re going to even attempt these abrasive filaments, just get a hardened nozzle from the get-go and save yourself some pain.

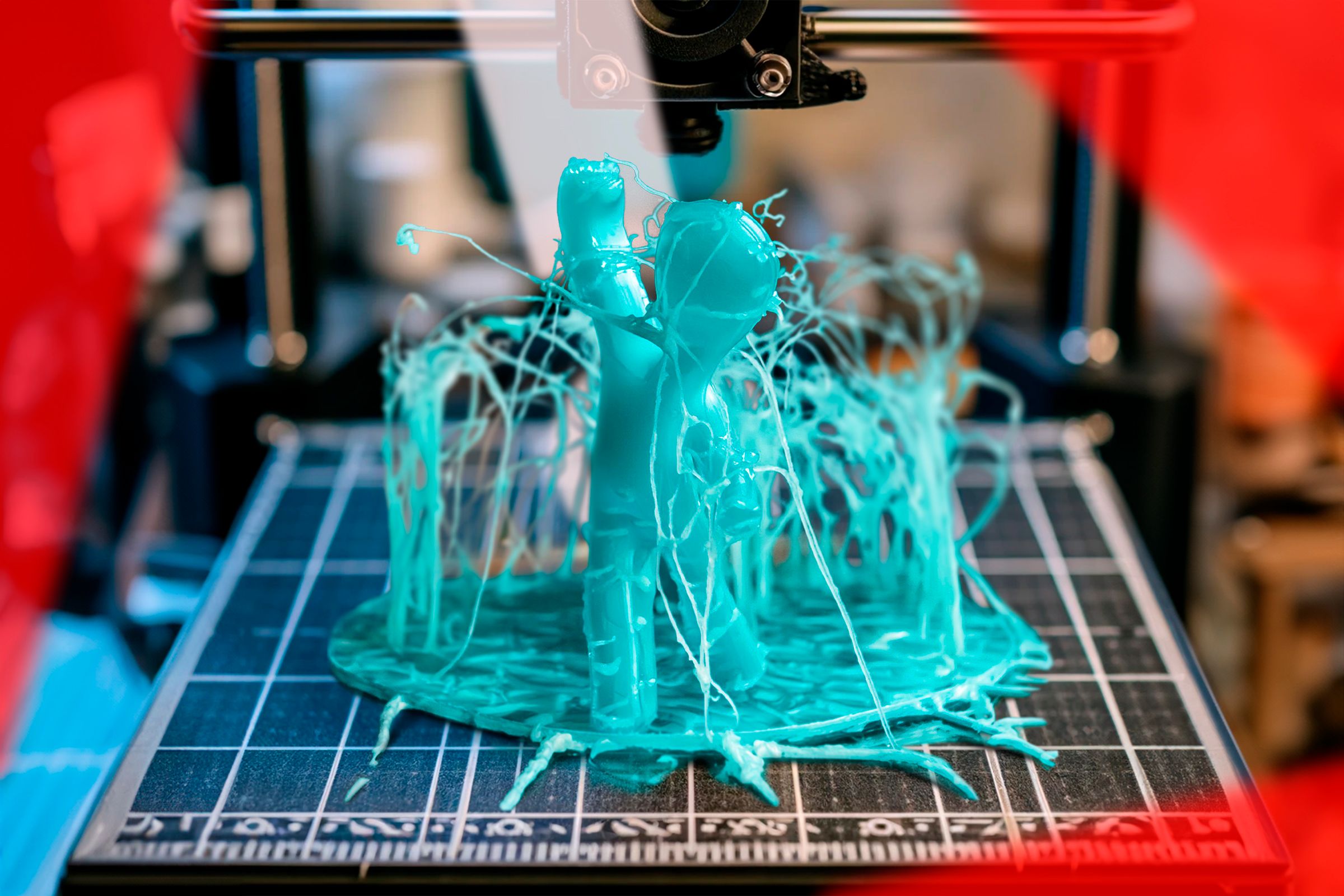

Stringing For No Apparent Reason

Stringing happens when the nozzle moves from one part of the print to another without printing, and leaves a little gossamer string of filament behind. Some stringing is inevitable with some models. For example, when I print articulated frogs, there’s always a little bit of stringing between the toes. This is an easy cleanup with a brush, but stringing can get so bad and the strands so thick, that the model has to be thrown away.

What’s maddening is that it’s not always happening for the same reason. The first thing you should try is increasing the amount of “retraction” when slicing your prints. This is basically when the printer pulls the filament back up while it’s traveling between points, so that you don’t get a little string from the tip. However, the amount of retraction necessary can depend on the specific filament you’re using, and what temperature you’re printing at.

If you always use the same filament, you can get this dialed in pretty perfectly, but I change filaments often, which means I have to tweak or have different profiles for them. If more retraction doesn’t help, my go-to solution is to lower the temperature closer to the minimum print temperature for that filament. The colder I print, the less chance of stringing, and as long as I stay within the rated range, I’ve yet to have an issue.

Extruder Grinding

While we’re on the subject of retraction, if the setting is too aggressive and the model you’re printing needs lots of retraction, you may end up with extruder grinding. The constant back-and-forth can grind out and bulge the film between the extruder’s wheels. This can lead to blockages and breakages, which is something I had to deal with a lot with some filaments.

Even worse, the grinding can spew little bits of filament all over the inside of your extruder, getting into gears and causing all sorts of issues. It was so bad for me at one point, that I just replaced the entire extruder.

If you’re getting breakages or blockages above the heat break (on a direct drive printer like my K1 Max) it’s worth inspecting the filament after a print to see if you can see evidence of grinding. Then tone down the amount or frequency of retraction.

As user-friendly as 3D printing has become, there’s still a long list of common and irritating issues that can arise. These are just a few of my own bugbears, but I’m sure plenty of you with more hours under the belt have worse stories to tell, and probably better advice for me to avoid or fix these issues. In the meantime, I have another order of plastic frogs to fulfil.