With escalating U.S. tariffs on Chinese imports and mounting supply chain pressures, Tim Cook has made it clear that Apple is intensifying its manufacturing shift to India to sustain its iPhone supply.

Foxconn, Apple’s largest assembly partner, plans to double iPhone production in India by the end of 2025, aiming to produce 25-30 million units, up from approximately 12 million in 2024. Tata Electronics has also commenced operations at new facilities, including one in Hosur, Tamil Nadu, supporting increased output of older iPhone models.

“If you look at the quarter that we’re now inif you look at the US, over half of the U.S. sales of iPhone come from India,” Apple CEO Tim Cook said in a May 1 interview with CNBC, highlighting the scale of Apple’s India manufacturing shift.

Historically, India’s iPhone production focused on local or lower-cost markets. However, the current strategy positions U.S. shipments as a central component, signaling a significant shift in Apple’s manufacturing approach.

Q2 2025 earnings reflect U.S. market emphasis

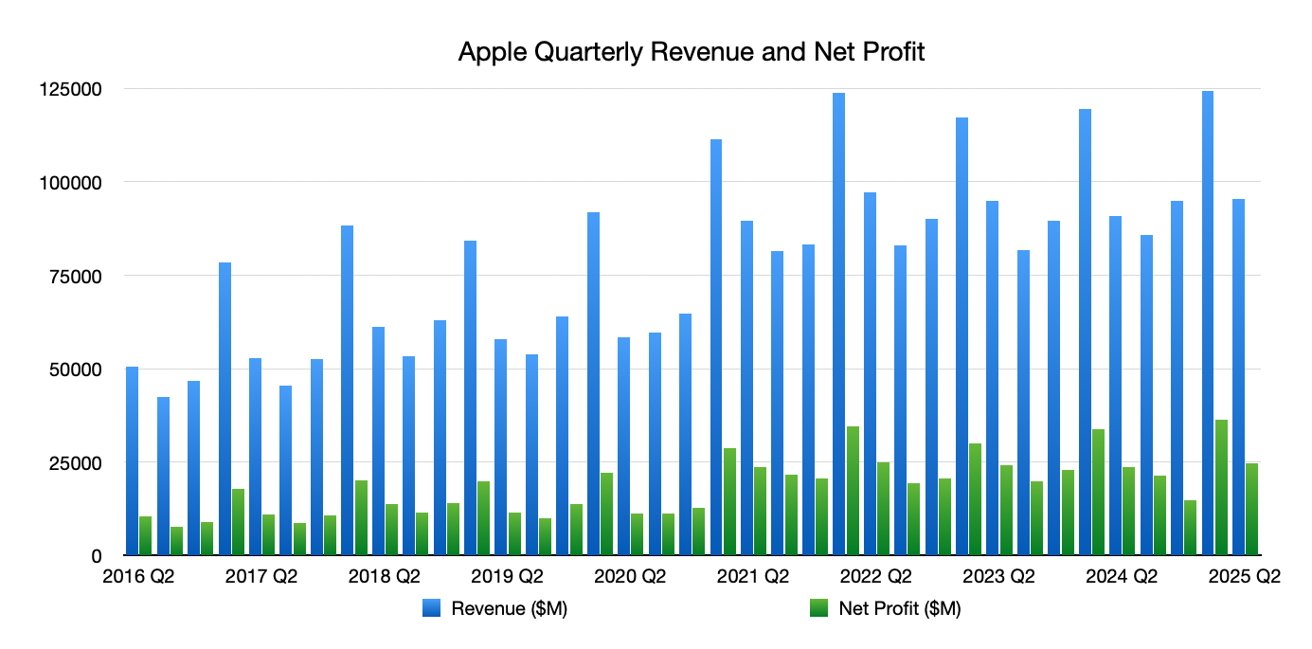

In its fiscal Q2 2025 earnings report, Apple announced revenue of $95.4 billion, a 5 percent increase year over year, and diluted earnings per share of $1.65, up 8 percent.

Services revenue reached a new all-time high, with growth observed across all product categories. Cook attributed part of this success to the introduction of the iPhone 16e, a model targeting price-conscious consumers, which is likely integral to Apple’s export strategy from India.

Chief Financial Officer Kevan Parekh reported that Apple’s active device installed base achieved a new all-time high, crediting customer loyalty and satisfaction. He also highlighted $24 billion in operating cash flow and noted that the company has returned $29 billion to shareholders this quarter through dividends and buybacks.

Strategic shift to mitigate tariff impacts

The move to Indian manufacturing is partly driven by the imposition of U.S. tariffs on Chinese goods, which have reached up to 145 percent. By diversifying its production base, Apple aims to avoid tariff-related costs and pricing volatility in its largest market.

Additionally, Apple seeks to enhance supply chain resilience. The COVID-19 pandemic exposed vulnerabilities in China’s manufacturing sector, leading to significant delivery delays and revenue shortfalls.

Expanding production in India reduces the risk associated with overreliance on a single country.

Navigating challenges in India’s manufacturing landscape

Apple’s expansion in India faces several challenges. Suppliers with Chinese ownership have encountered resistance from Indian regulators, complicating the integration of established component manufacturers.

India’s infrastructure, labor laws, and production scale differ from the highly optimized Chinese model Apple relied on for decades. Still, the pace of development is rapid.

Apple appears determined to make India its next major production hub. Environmental targets are part of the push. The company says it has cut its carbon emissions by 60 percent over the past decade, with new Indian factories powered by renewable energy contributing to that goal.

For American consumers, the shift may mean steadier supply and fewer pricing shocks in future iPhone cycles. If Apple succeeds in moving most U.S.-bound iPhone production to India by 2026, it will mark one of the most significant changes to its global manufacturing network in years.