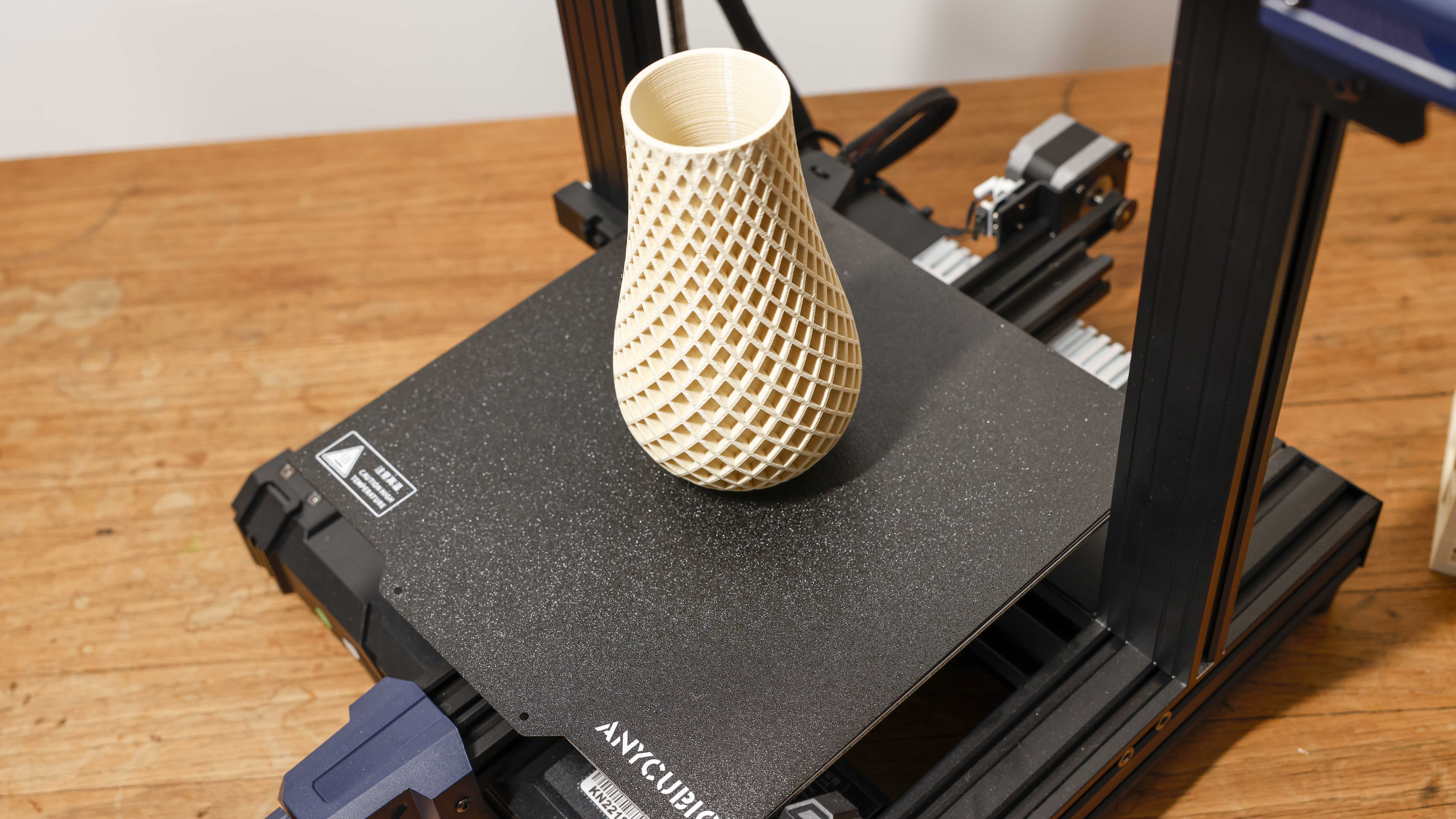

The AnyCubic Neo is a powerful 3D printer that sits between the Kobra Go and the Kobra models and offers features that instantly make it an attractive choice for 3D printing enthusiasts. The Neo features a one-touch leveling system, integrated extruder for precise filament extrusion, adhesive PEI spring steel platform for easy removal, 10-minute easy set-up, high-speed printing, decent creation dimension, worry-free smart sensors, knobs for easy adjustment, good filament compatibility due to the direct drive extruder, and quiet printing. The Neo is an excellent choice for a reliable 3D printer with great features and affordability.

Design

The AnyCubic Kobra Neo is a 3D printer with user-friendliness at its heart and provides a high-quality 3D printing experience for printers at any experience level. It has a sleek, modern design with injection molded parts and metal extrusions. Again, as with the other Kobra models, AnyCubic has gone to great lengths to ensure that all electronics and cables are neatly integrated, making this 3D printer a lot safer and easier to use and move than many other budget offerings.

Specs

Print Technology: Fused Deposition Modeling

Build Area: 250 x 220 x 220mm

Minimum Layer Resolution: 0.05

Maximum Layer Resolution: 0.3

Dimensions: 445 x 443 x 490mm

Weight: 7.4kg

Bed: Double-sided PEI-coated Metal Steet

Print Surface: Textured

Software: CURA

Materials: PLA / ABS / PETG / TPU

Print Speed: ≤100 mm/s (Max speed)

The main design goes along the standard cartesian model with a robust and durable frame, and all parts are well-made and finished. When the printer arrived, it was around 90% complete, and initial construction and set-up took less than 10 minutes. Essentially you pop in a few screws and cables and switch on; there’s nothing too challenging, although an extra pair of hands does help when assembling the vertical frame.

The AnyCubic Kobra Neo has a build volume of 50mmx220mmx220mm and a layer resolution of 0.05 – 0.3 mm. It’s nice to see that this build platform is once again a magnetic sprung steel design and double-sided, so if you mess up one side of the sheet, you can flip it over. This design also makes it incredibly easy to remove prints once the sheet has cooled slightly.

The tool head features a standard 0.4mm nozzle designed for a 1.75mm diameter filament. It also uses a direct drive extruder and has broad material compatibility. Loading filament is straightforward, with a lever enabling filament to be inserted, and then the load filament option can be selected using the push dial interface. Unloading filament works in much the same way.

All interactions with the machine are made through a small color LCD screen; this isn’t a touch screen and instead uses a push function dial to scroll through options with a push to select. It’s pretty primitive but does the job.

Once the machine is constructed and powered on, a quick leveling process is required. Here AnyCubic uses a non-contact magnetic probe to handle the bed leveling. Once the process from the menu Leveling > Auto Leveling has been selected, the process starts automatically. Unlike some other printers, there is no final fine-tuning to the process, and although highlighted in the manual, manual Z-Axis adjustment is essential after the auto leveling.

As with all 3D printers, it’s always worth checking the quality of the first layer; a minor adjustment is almost always needed. Using the Owl test print, it took about five attempts to print the first layer before I was happy with the results, taking a Z-Axis adjustment of 3.200mm, so quite a bit!

The AnyCubic Kobra Neo has been designed to be used with any Slicer software, although CURA 4.1.2 is the option included on the SD card that ships with the machine. Again AnyCubic hasn’t included a custom build of CURA, so it’s up to you to enter the details into the machine options. This isn’t difficult but can confuse beginners; thankfully, the manual has incredibly detailed instructions and does include three material profiles for PLA, ABS, and TPU to get you started.

Overall the design of the machine is simple, with many similarities with the excellent standard Kobra, just at a lower price and without the touchscreen interface.

Features

The AnyCubic Kobra Neo is a 3D printer designed for the home user. It incorporates several features that make it an excellent choice for any user looking to get into 3D printing.

The automatic 25-point leveling system ensures the printing platform is level and stable, giving an excellent foundation for printing. The printing platform is 8.7 x 8.7 inches / 220 x 220 mm, providing plenty of room for larger prints. Filament run-out detection is optional, allowing users to monitor their filament usage and ensure they don’t run out during a print.

The Kobra Neo is compatible with PLA, ABS, PETG, and TPU filaments, giving various material options. The nozzle size is ø 0.4 mm and is replaceable, allowing the user to use different nozzle sizes for other materials and print qualities.

The nozzle temperature can reach up to 500 °F / 260 °C, and the heated platform temperature can reach up to 230 °F / 110 °C. The maximum printing speed is 100 mm/s. The Kobra Neo has a 2.4-inch LCD screen with a control knob for easy navigation of menus and settings.

The Z-axis is driven by a single threaded rod for smooth and accurate movement. The maximum printing dimensions are 250 x 220 x 220 mm (HWD), and the machine dimensions are 490 x 445 x 443 mm (HWD).

Performance

AnyCubic machines have become increasingly easy to construct and set up, with the process for the Neo taking less than ten minutes. Once complete and the auto bed leveling had run through the checks, manual height adjustment, as previously mentioned, was needed before the test prints could be run through the system.

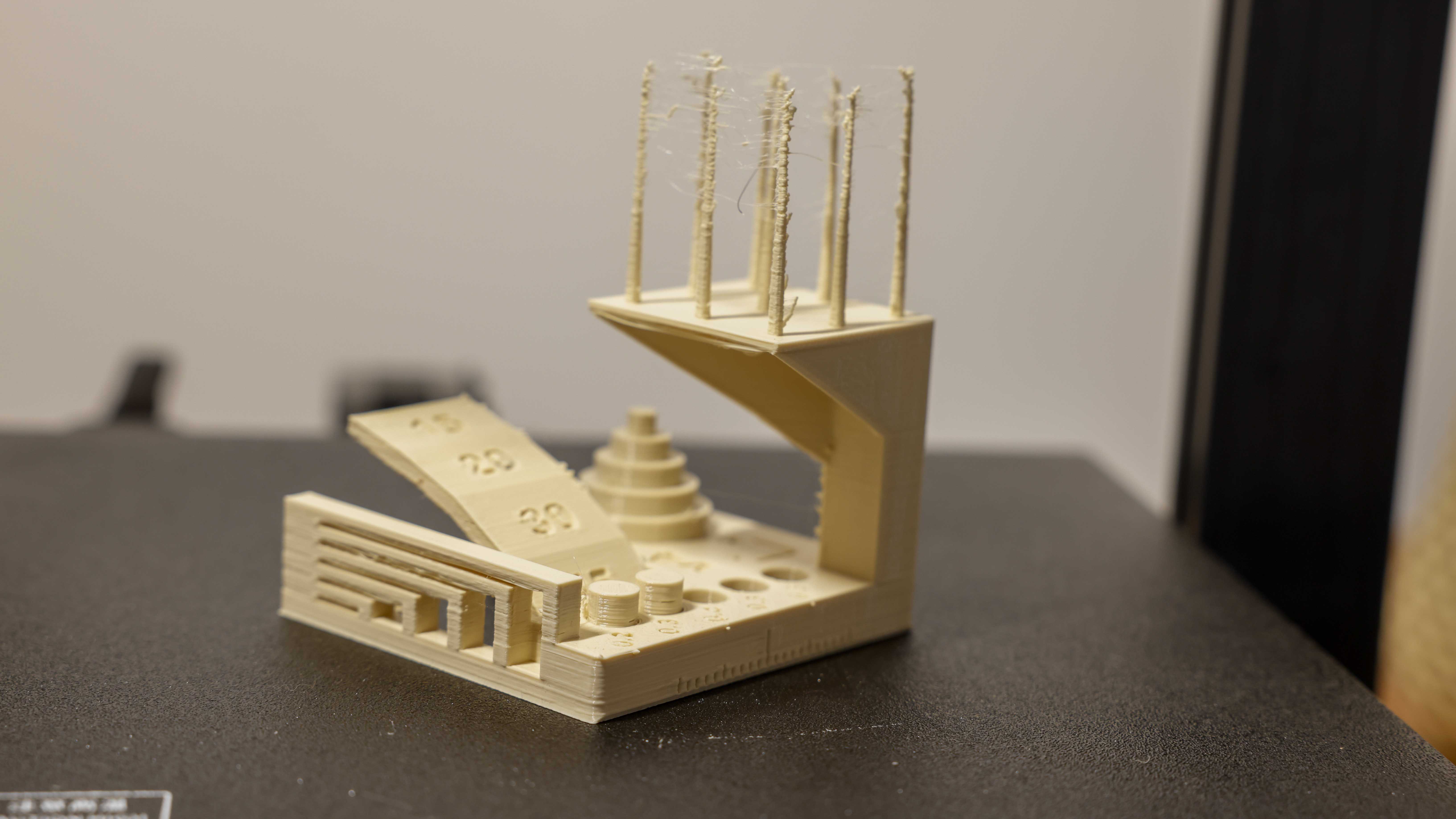

The initial prints that ship with the machine, the test model, and the height gauge printed quickly and at a decent quality. As the models print, the initial layers are laid down at 20mm/s which consistently gains excellent results.

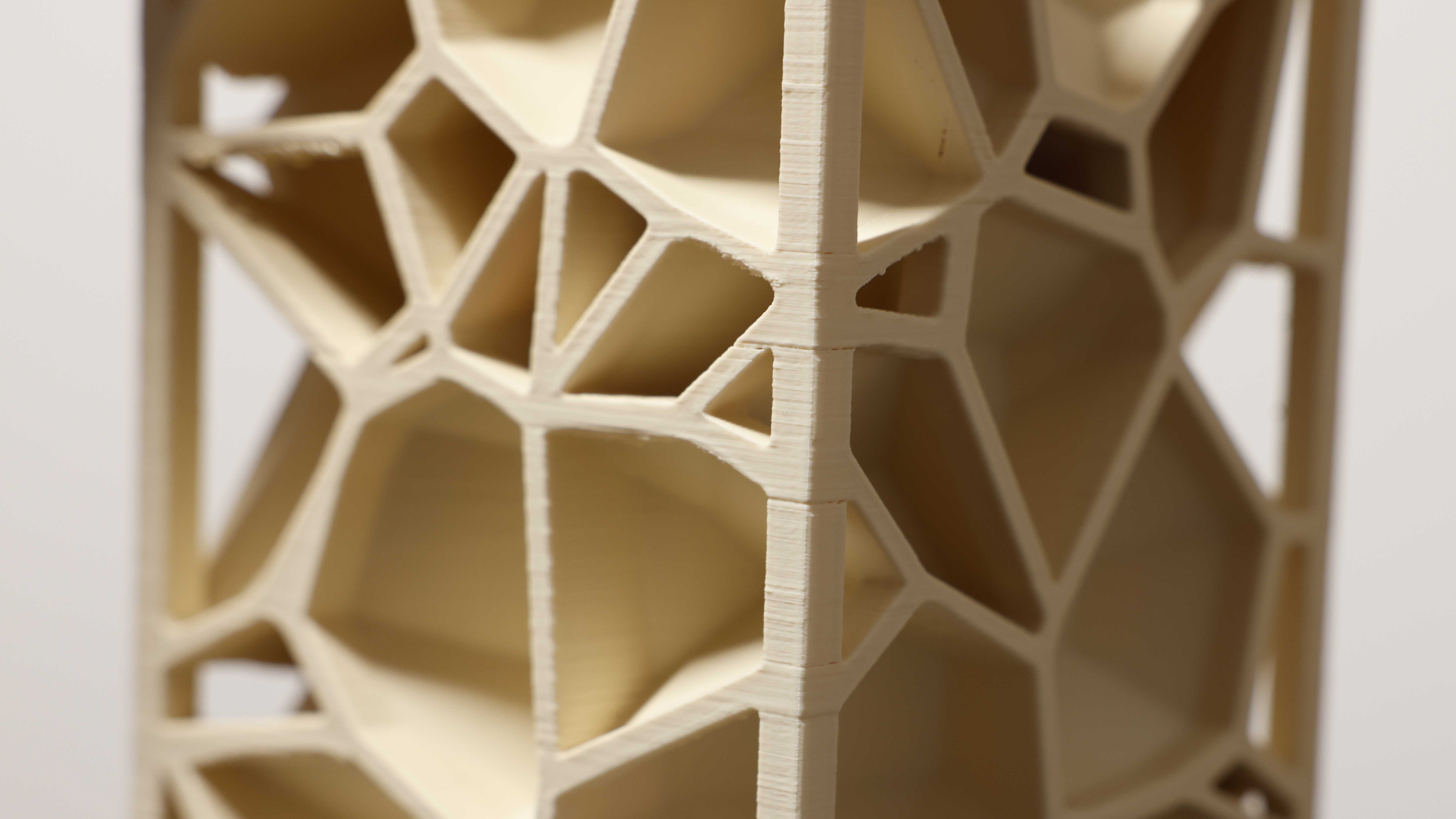

Once the settings were fine-tuned, the accuracy of the filament flow from the tool head was unmistakable. Clean lines and good accurate placement of filament on the print bed provide a solid platform for the rest of the print. As the print builds, the surface quality looks visually impressive, with minimal signs of layering at the higher qualities.

Using Normal quality for the vast majority of prints through this test, the results are impressive. The need for support on some models was required, but cooling from the small hotend fans head is fast, enabling better control of bridging and overhang areas than I expected from a machine at this price.

Overall the aesthetic quality of prints in Normal settings was excellent. Switching to extra fine and again, the printer handled the finer printing well, although there are a few minor glitches in the quality of the print walls as the thinner filament strings are laid down.

Switching to low-quality, Extra Course is exactly what the printer does, the prints are OK, but Extra Course is definitely the best description for them.

After a time with the printer, you know what it can and can’t do. Mostly it’s highly proficient as a home enthusiast printer and will be an ideal solution for model makers. For those wanting the printer to make mechanical working parts, this won’t be the printer for you; however, as the dimensional accuracy test proves, it is still impressive.

Print quality

Dimensional accuracy – score of 5

Target 25 = X: 25.01mm / 0.01mm Error | Y: 25.22mm / 0.22mm Error

Target 20 = X: 20.13mm / 0.13mm Error | Y: 20.07mm / 0.07mm Error

Target 15 = X: 15.08mm / 0.08mm Error | Y: 15.03mm / 0.03mm Error

Target 10 = X: 10.13mm / 0.13mm Error | Y: 10.10mm / 0.10mm Error

Target 5 = X: 5.02mm / 0.02mm Error | Y: 4.87mm / 0.13mm Error

X Error Average = 0.074

Y Error Average = 0.11

X&Y Error Average = 0.092

Fine Flow Control – score of 2.5

Fine Negative Features – score of 3

Overhangs – score of 2

Bridging – score of 2

XY resonance – score of 2

Z-axis alignment – score of 0

Adding up the totals gives a final score 16.5 out of 30.

Verdict

The AnyCubic Kobra Neo 3D printer provides excellent printing and handling quality. It is easy to use and set up, and the prints come consistently and of high quality. The printer is well-built and can handle a variety of materials with ease. The price of the printer is also incredibly reasonable, and it offers excellent value for money.

As an entry-level model, there’s a lot on offer, and the print quality does challenge that of printers at least double the price. While the printer is good, the low cost has been achieved by going light on some of the more advanced features. For example, there is no standard touchscreen or filament run-out sensor.

Again there’s also the issue with CURA and AnyCubic simply supplying you with the downloadable version without customization. Other manufacturers take things a little further by creating their custom CURA builds; the software is open-source. However, the included instructions are excellent, so even though the software isn’t out-of-the-box ready, it doesn’t take more than a couple of minutes to set up.

Overall, the AnyCubic Kobra Neo 3D printer is an excellent choice for anyone looking for a reliable and affordable 3D printer, whether they’re new to 3D printing or want a cheap 2nd machine.