3D printing using plastic filament or light-cured resin is now a mature technology that many of us use in our homes, but 3D printing is evolving in many different directions, and one of the most exciting new takes on this technology is rapid liquid 3D printing.

How Does Rapid Liquid 3D Printing Work?

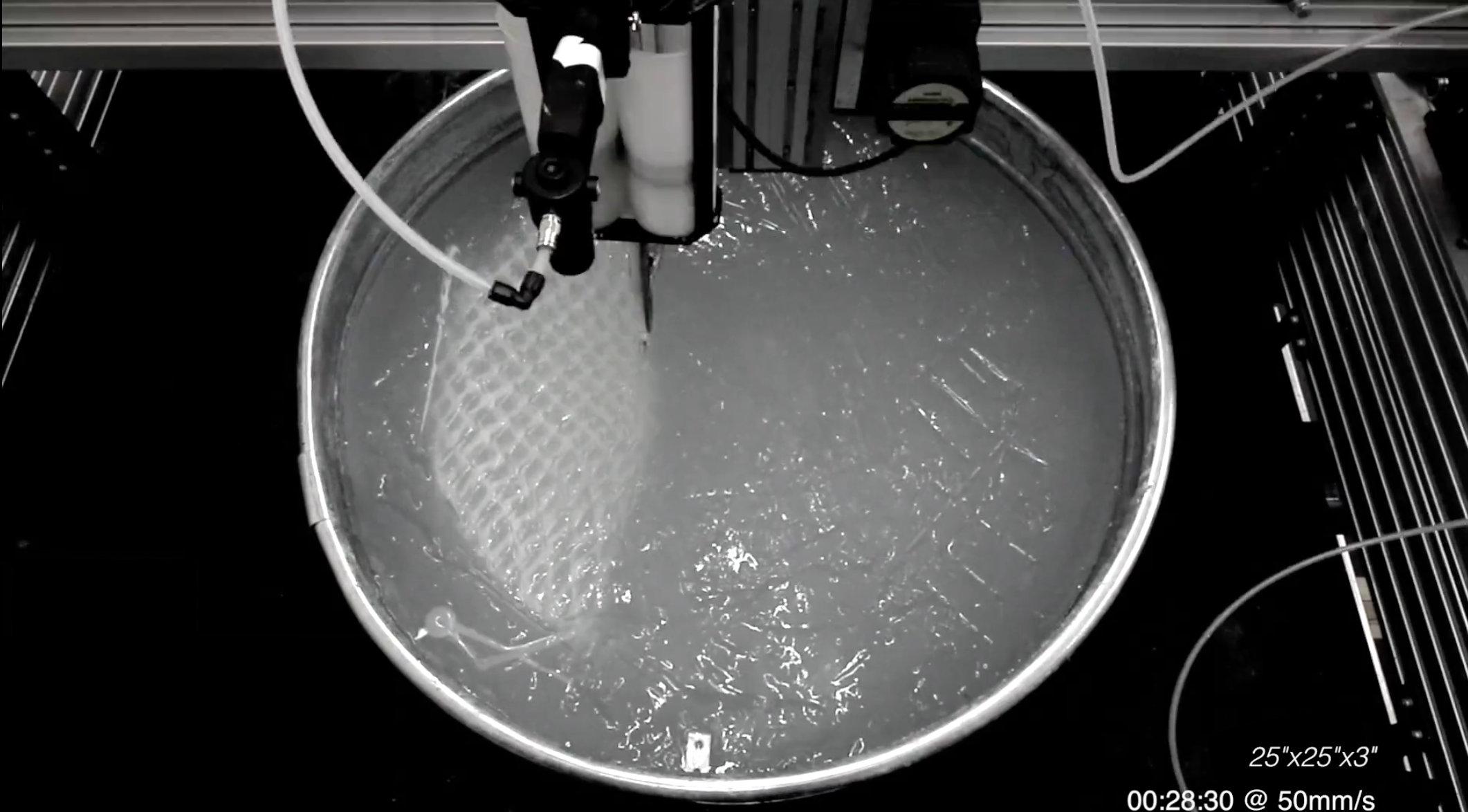

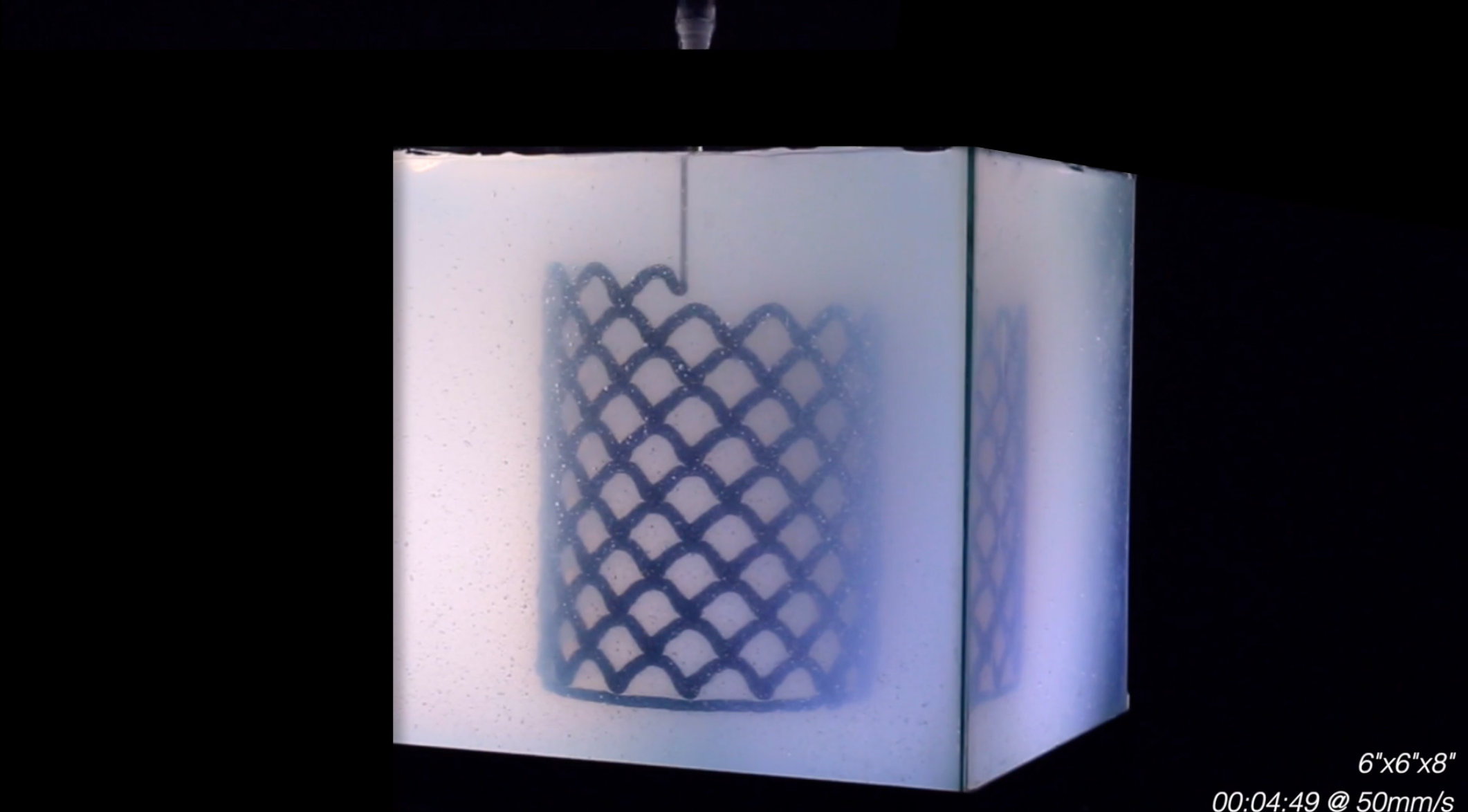

This method, developed by MIT and Steelcase makes use of a print head and a gel suspension in a tank. The print head penetrates the gel and releases material that instantly cures.

The gel suspension supports the print, so there’s no need for complex supports as you would have with a filament or resin printer. Once the print is done, you simply pull the object from the gel suspension, and it’s ready to go.

What Makes This So Exciting?

One of the biggest drawbacks of modern 3D printing, is that it’s incredibly slow. Even the fastest printers, whether using filament or resin, take hours to create objects. These objects also need lots of post-processing to clean them up. You need to remove imperfections, and remove lots of wasteful support structure.

In contrast, this rapid liquid printing method really is quite rapid! Just check out some of the clips in this overview video. Many complex prints are done within just an hour or two.

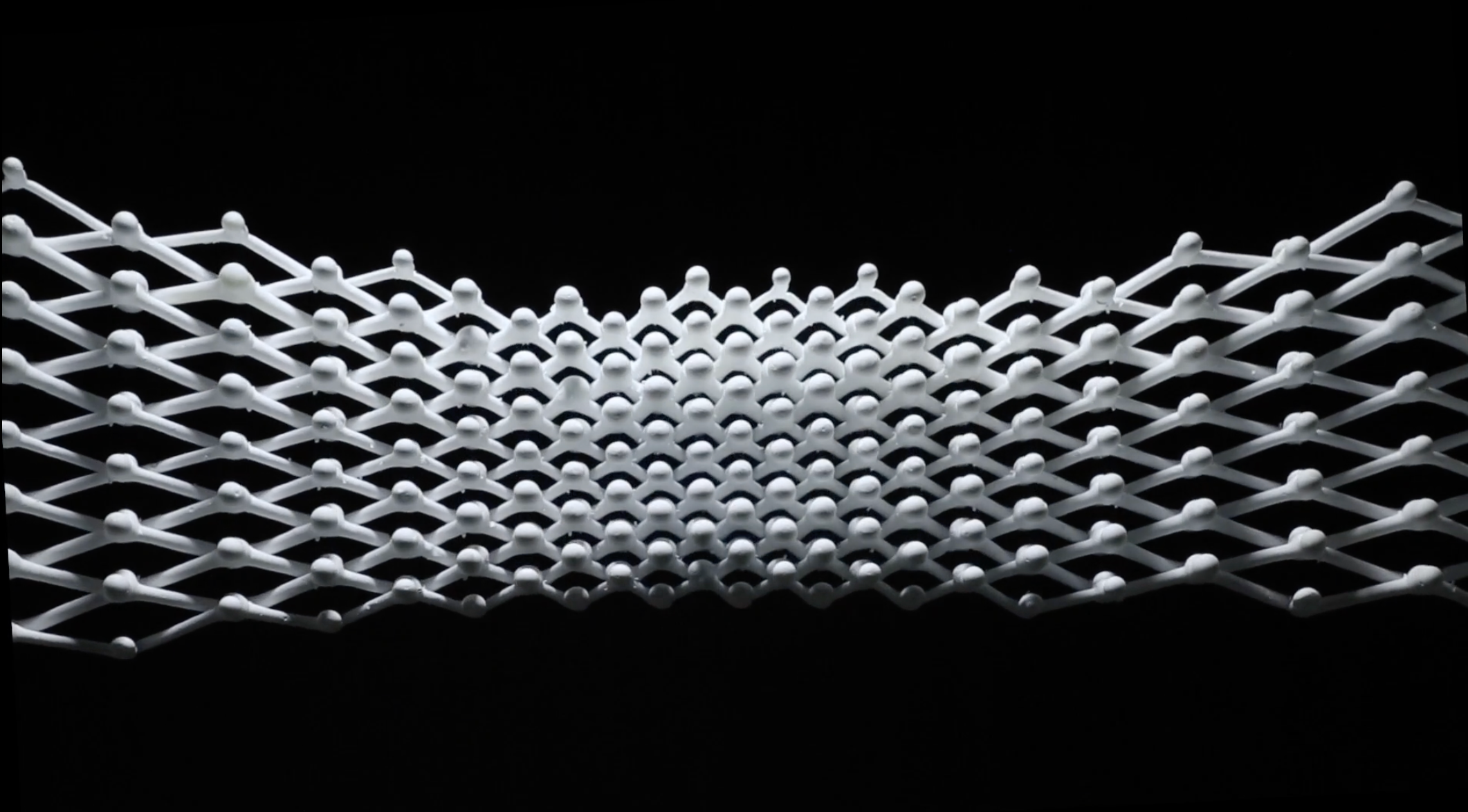

Apart from being fast to print, this method requires no post-processing. Just take your finished object from the gel, and rinse it with water. This gel-suspended printing process also allows for objects with highly-complicated internal geometry, so it opens up all sorts of interesting possibilities.

Creality K1 Max

The Creality K1 Max is a large volume consumer 3D printer with a high-speed Core XY design, and advanced AI-based automation systems.

What Can We Use This Tech For?

Right now, this printing method uses elastomers and silicone as the printing medium, and there are endless applications for those materials in the real world. One of the most famous demos of this technology has the machine rapidly printing handbags, but imagine printing custom silicone skins for prosthetic limbs, or the numerous soft material parts used in the automotive and aerospace industries. Think of custom furniture components, or shoe parts that are based on scans of your own feet.

What’s the Catch?

There are some obvious caveats to rapid liquid 3D printing. First of all, it needs a tank filled with that special gel. This is going to be a challenge to maintain, and even 3D resin printing enthusiasts would likely cringe at the idea of working with a big tub of goo. So I don’t see this becoming a home printing technology at any point.

Then there’s the material limitation. This system can only print using a relatively small set of polymers that can be printed and cured in a compatible way. So you’re limited to objects that make sense for the material in question.

It should also be obvious that, given the speed and material medium, this method isn’t going to have the precision and consistency of other 3D printing technologies. So if you make five prints of the same thing, they might vary a little here and there, and you’re not going to have fine surface detail features.

The Future of Rapid Liquid 3D Printing

Right now, this technology is still in its experimental stage. The initial academic research has been spun off into a company known as the Rapid Liquid Print Company, which will work to commercialize the technology.

Personally, I see this tech taking off for companies where mass customization makes sense, such as the medical field or shoes and textiles. Mass customization, where you get the benefits of mass production and personal customization, has always been one of the big selling points of 3D printing as a whole, but has never really been realized on an industrial scale.

Maybe in the not-too-distant future, you’ll be scanning your body with your phone and placing an order for something perfectly fitted to you, all thanks to a big tub of goo.