Last updated

Thanks to automation, the Cupertino-based tech giant plans to reduce the number of workers assembling the iPhone by as much as half, but that could have disastrous effects on international labor markets.

Apple has always known that its business was heavily reliant on workers in its international factories, such as Foxconn, to ensure the iPhone would be ready to ship in the fall.

In 2020, Apple learned just how important they were. The COVID-19 pandemic caused supply chain shortages and delays that the company is likely still recovering from.

And, it learned that lesson again in 2022, when hundreds of workers rioted at Foxconn’s main iPhone factory in Zhengzhou, China. Workers alleged that both pay and conditions were abysmal, and videos showing Hazmat-clad police officers beating the protesters surfaced on social media.

According to The Information, Apple’s senior vice president of operations, Sabih Khan, had sent an edict telling his managers to “reduce the number of workers on iPhone final assembly lines by as much as 50% over the next few years.”

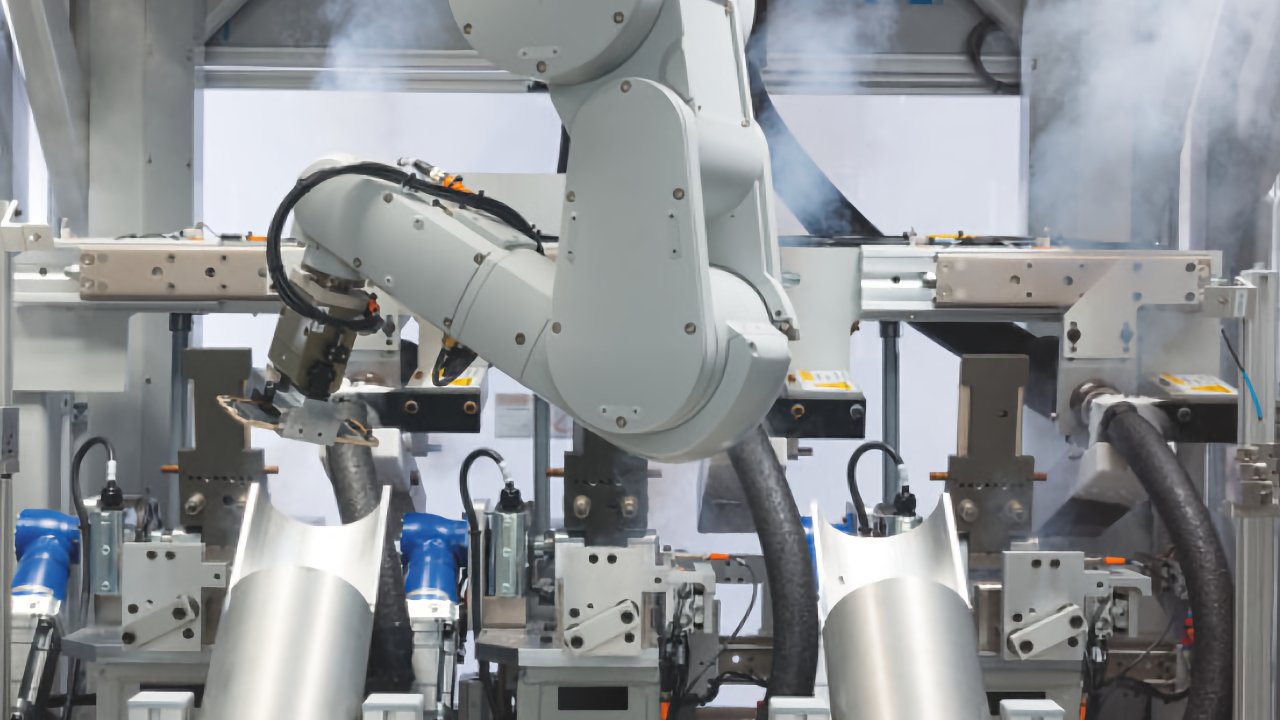

This meant the company would need to resurrect old automation projects it had previously postponed due to high short-term costs. However, the company has since heavily invested in automation, which allegedly was utilized in producing the iPhone 15.

The push for automation reduces the number of workers and, therefore, could theoretically reduce some of the cost of producing the iPhone — and eventually other products. However, the machines used in automation can cost hundreds of millions of dollars, and many of Apple’s manufacturing partners aren’t willing to make that investment.

Apple’s real reason is to avoid the problems inherent to relying on human workers. After all, machines don’t get sick, don’t demand better conditions, and don’t require the same number of accommodations that human workers do.

Of course, machines can also be installed and operated in areas that aren’t in places that aren’t actively embattled in US trade-regulation battles, too.

But, according to the report, there have been some issues. Robots used for testing were having difficulty placing small pieces with enough precision, and more with adequate screw placement and proper torque.

The impact on China’s labor force

It is unclear what that would mean for China’s labor market, which supplies millions of workers to Apple’s supply chain. If these workers were suddenly laid off, the effects could be disastrous.

Apple’s 2023 supply chain report showed that the company dropped the number of employees it monitors at manufacturing partners from 1.6 million in 2022 to 1.4 million in 2023. That’s a reduction of 12.5% in a year and the first time that figure shrank in over a decade.

Apple’s automation efforts have been successful in part due to companies it has acquired along the way. In early 2024, Apple purchased Canadian startup DarwinAI, which The Information points out can be used to inspect components like printed circuit boards for defects.

Apple also acquired Drishti, a startup that aims to help manufacturers identify footage of assembly lines to identify bottlenecks in real time.

In 2024, Apple planned to automate the installation of buttons and other components on the upcoming iPhone 16. However, due to a high rate of defects, the company has decided to delay its headcount reduction targets for another year.