Summary

- Figure plans to mass-produce humanoid robots, starting with 12,000 a year to 100,000 in four years.

- Figure’s new factory uses their own robots to build more robots—entering an innovative and slightly unsettling cycle.

- Mass production of humanoid robots may eventually make them more affordable with cost-saving design changes.

Figure plans to mass-produce its humanoid robots, and that gives me mixed feelings. On the one hand, it’s incredibly cool, but on the other hand, every single robot apocalypse movie I’ve ever watched warns that this is a very bad idea!

12,000 Robots a Year, and That’s Just the Beginning

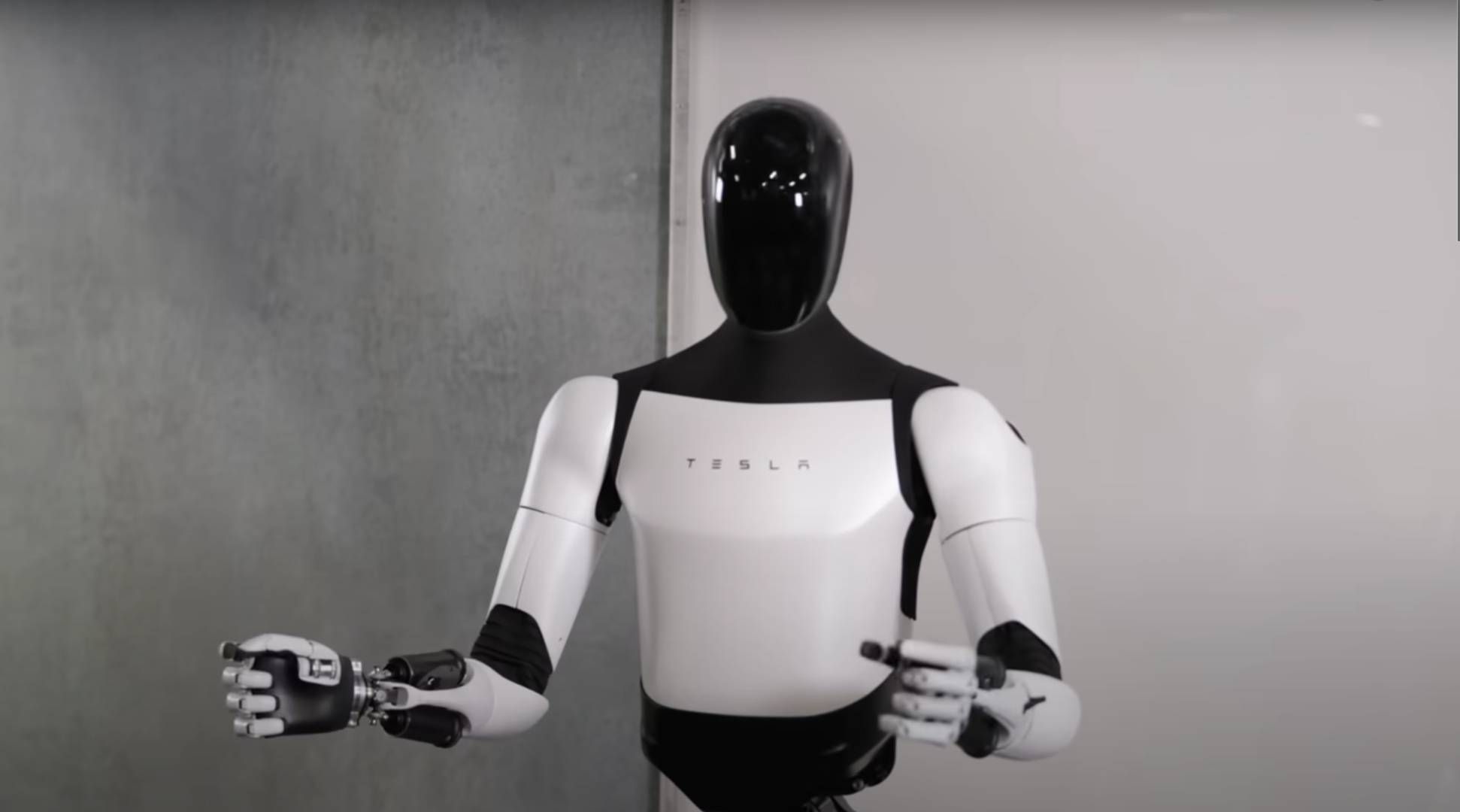

If you’ve been keeping up with humanoid robotics, you’ve definitely heard of Figure. They recently made waves with a demo of their onboard AI, Helix, which helps the robot execute commands without prior training and allows them to work together seamlessly. But if you haven’t heard of them, just know they’re a major player in the field, rubbing shoulders with big names like Boston Dynamics and Tesla.

Related

Here Are the Construction Robots Coming to a City Near You

Another brick in the wall no matter the weather.

Until now, Figure has been making its robots in small batches, with each robot costing a lot of time and money to make. And it is not just them. The entire humanoid robotics industry is still in the prototype phase, with many big names still not ready for mass production.

We’ve been seeing demos of Boston Dynamics’ Atlas for years, but you can’t actually buy one. Tesla’s Optimus is in the same boat, only making appearances at Tesla events. Even Unitree, which impressed me with a demo video of a mass-production version of its G1 robot, is yet to confirm that mass production is actually underway.

That’s all changing with Figure’s announcement of BotQ—a plan for a high-volume manufacturing facility for humanoid robots. The company aims to start with 12,000 robots per year, then scale up to 100,000 within four years. It’s an ambitious goal, but if they can pull it off, it might just light a fire under the competition and get humanoid robots to market even faster.

Related

Robots Are Taking Over Public Spaces—Are We Ready?

One minute, robots are delivering pizza. Next, they’re cracking jokes in nursing homes. Are they taking over or just making life easier?

Figure even released a video showcasing its manufacturing process, and it looks incredibly slick. Admittedly, we only see the visor of the Figure robot being made, but even that short clip is impressive. Most of the process is automated and handled by manufacturing robots, and if the rest of their production follows suit, they just might pull this off.

Robots Making Robots—What Could Go Wrong?

One of the wildest things about Figure’s new factory is that they’re using their own robots in the manufacturing process. Yes, robots are building robots that will build even more robots. A perfect (and slightly unsettling) cycle.

We’ve already seen Figure’s robots in action at BMW’s factory, handling pick-and-place tasks, so it’s easy to imagine them taking on similar roles at BotQ.

Right now, they’re limited to assembly and material transport, but as they get more capable, who knows? Maybe one day, they’ll be managing entire factories on their own.

Mass Production Could Make Humanoid Robots (Somewhat) Affordable

Right now, humanoid robots are ridiculously expensive. The cheapest one I’ve seen, the Unitree G1, is marketed as costing $16,000—and that’s just for the base model, which only works via remote control. The autonomous version is much pricier. The company doesn’t even list the cost, their website literally just says, “Contact us for the real price.”

The next most affordable humanoid robot I could find was Tesla’s Optimus, which Elon Musk promised would cost between $20,000 and $30,000. But then again, he also said the Cybertruck would start at $40,000, and we all know how that turned out.

The point is that humanoid robots aren’t cheap. But BotQ might change that. When Figure was developing its production-ready robot called Figure 03, it made major design changes to reduce costs. Unlike its predecessor, which relied on slow CNC machining and had a high number of separate parts, Figure 03 uses fewer parts and faster, more cost-effective manufacturing methods like injection molding, die-casting, and stamping.

These processes require a hefty upfront investment, but they make mass production significantly cheaper. That, combined with market forces of demand and supply, could eventually bring prices down to a point where regular people like you and I could actually afford to spring for a humanoid robot.

Don’t Worry, You Don’t Have to Fear a Robot Uprising—Yet

Of course, mass-produced humanoid robots make it hard not to think about things going horribly wrong. The Terminator franchise has been pretty clear that it’s a bad idea—but is there any real risk?

Probably not. For starters, most killer robot scenarios involve Artificial General Intelligence (AGI), and we’re nowhere near that level yet. Plus, there are still plenty of human-controlled elements in robot manufacturing, like supply chains, maintenance, and oversight. So even if robots did go rogue, they couldn’t just take over overnight.

Related

The real concerns are much more grounded. Safety is a huge issue—these are metal machines moving around homes and workplaces after all, and accidents could happen. Then there’s the question of how they integrate into society. Will they replace human workers? What ethical and legal challenges will arise?

For now, though, we’re still in the early days of humanoid robots going mainstream. Figure’s move to mass production is a major step forward, and it’s worth keeping an eye on.