TSMC’s U.S. chip production efforts won’t be making the latest chips for Apple products for the foreseeable future, with factories that haven’t broken ground lagging roughly five years behind Taiwan.

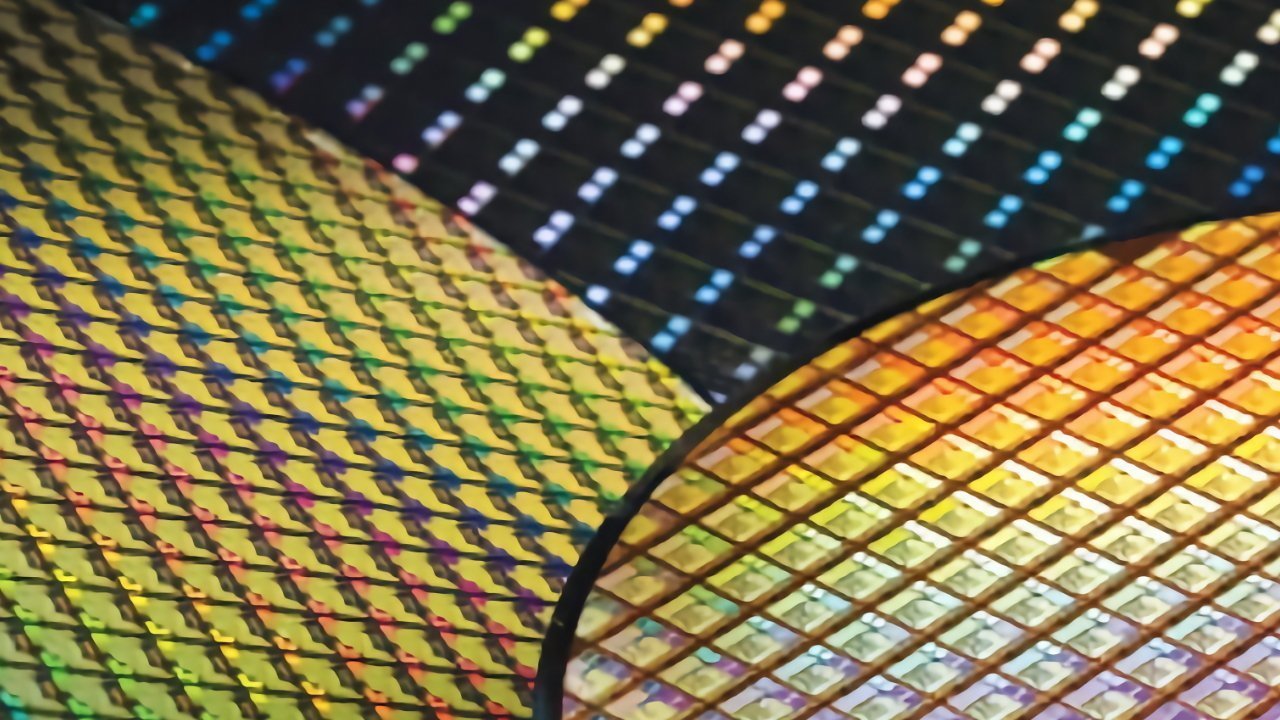

Apple chip partner TSMC has invested billions into its facilities in the United States, including its active Arizona chip foundry and a second facility due in 2028. While a third is also expected to be on the way, it could be the case that the factories won’t be greatly useful for producing Apple’s future A-series and M-series chips for quite some time.

According to a Wednesday report from Nikkei, TSMC is preparing to start operations at its second Arizona plant by 2028, which will be used to produce 3-nanometer chips. However, a third one is being planned in Arizona for 2-nanometer chip production.

This third facility will be a long time in the making, with the construction project’s conclusion and the first chips off the line scheduled to happen before the end of the decade, 2030.

If completely accurate, the report indicates that there will be a lag in process size between TSMC’s U.S. and Taiwan production of about five years.

iPhone timing

Currently, it is expected that the iPhone 18 Pro models will use an A20 Pro chip made using a 2-nanometer production process, which will see a release in 2026. However, TSMC is already working on perfecting the 2-nanometer process well in advance of mass production.

Production checks from March 22 by analyst Ming-Chi Kuo indicate TSMC is achieving yields above the 60-70 percent range, which is encouraging for full-scale manufacturing.

However, this is all production that is taking place in Taiwan, since TSMC’s facilities in that country are geared up to use the firm’s latest production processes.

As the U.S. facility won’t be up and running with 2-nanometer production until well after the iPhone 18’s launch, Apple will have to source the 2-nanometer chips from TSMC’s Taiwan operations, not the United States.

Currently, the active Arizona facility is making A16 chips under an N4 four-nanometer process. It may also be making the S9 SiP for the Apple Watch Series 9.

Silicon shield

The lag in process size between the United States and Taiwan is down to TSMC’s history in its home country, and preference to operate within it.

Aside from the timetable of developments, investments, and facility construction in the United States, there is another reason for the production lag: China.

The concept of a “Silicon shield” is that Taiwan’s chip economy is vast and important enough for the United States to be concerned about interruptions to it. So much so that the U.S. would be compelled to defend it if China were ever to invade Taiwan.

TSMC’s expansion into the United States could be a concern, especially if TSMC were to eventually reach parity between U.S. and Taiwan productions, as this would lessen the theoretical shield.

Construction in the United States is slowly accelerating, with TSMC making noises about improving its relationships with U.S. contractors on making the facilities.

TSMC declined to comment when it was asked about whether the accelerated expansion would reach a “Taiwan Speed” of two years to build a facility, rather than the existing five years in the U.S. for its first.

Building in the United States does help spread around production, minimizing the chance of disruption, such as a Chinese invasion. But it does so while putting its Taiwan operations at risk of being less important to the rest of the world.

To Apple, TSMC’s U.S. facilities can bring iPhone production closer to home, as well as spreading the risk of interruption to the supply chain. The latter is something that Apple has been working on for years by diversifying its manufacturing out from China.

All of the moves here are expensive ones, costing companies billions. They also take a lot of time to not only come into fruition, but to actually prove themselves to be good moves for Apple’s bottom line.