Summary

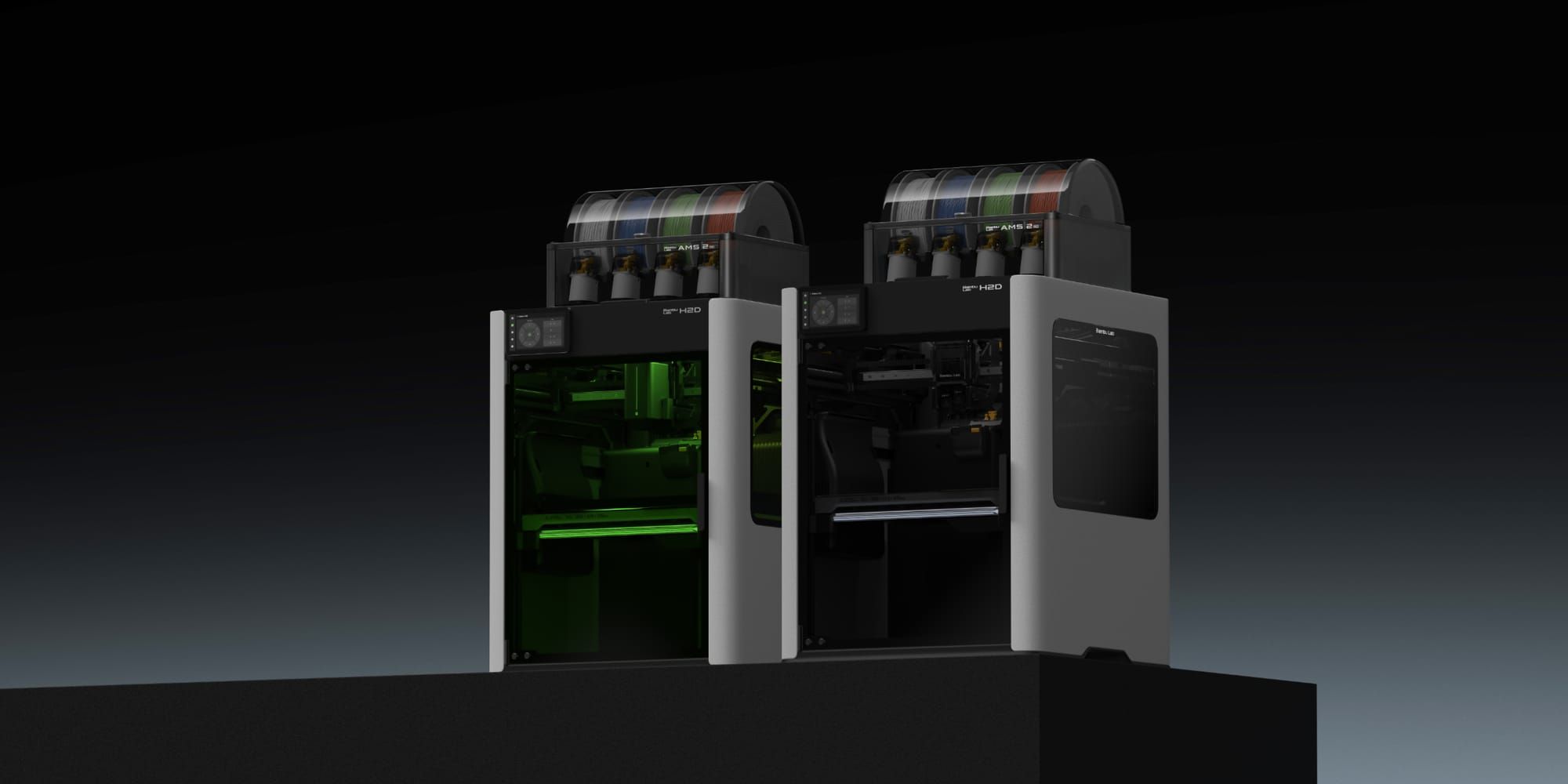

- Bambu’s just-announced H2D 3D printer offers a larger working area than its predecessors.

- The H2D also ups the ante by delivering the ability to transform from a 3D printer to a laser engraver/cutter, vinyl cutter, and pen plotter.

- While this seems nice, laser engraving/cutting generates a lot of soot and smells that aren’t great for 3D printing, requiring a lot of maintenance and work to have an all-in-one device.

Bambu Labs’ latest H2D 3D printer launched to a lot of fanfare. However, there’s one glaring issue with it that I just can’t wrap my mind around. Bambu wants you to give them $1,300 so you can convert your 3D printer into a laser engraver. Here’s why you shouldn’t do that.

Bambu Launches Its Jack of All Trades, Master of None 3D Printer

Bambu Labs is a cornerstone of the 3D printing community these days. With affordable yet extremely capable printers in their wheelhouse, a lot of people love what Bambu has to offer.

On the more premium side of things, the company’s original offering, the X1 Carbon and then later on the P1S, have become a go-to for print farms around the world. As such, people have been eagerly awaiting the successor of the X1C.

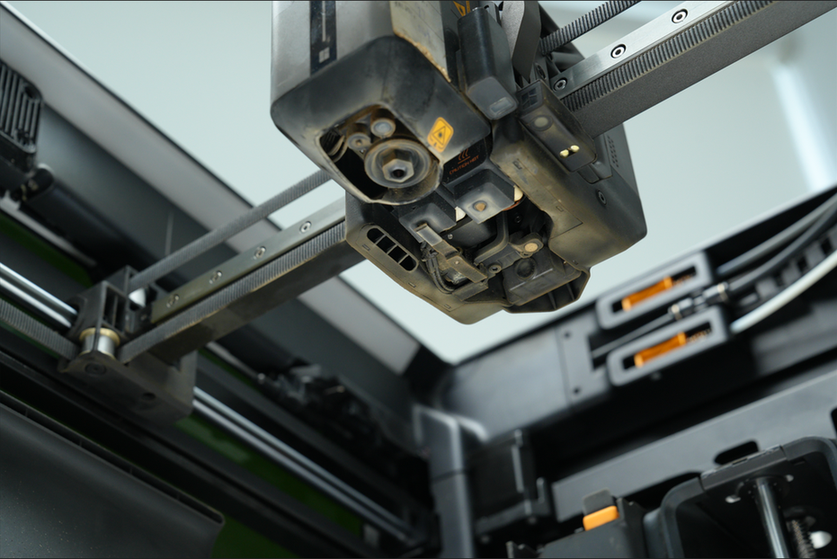

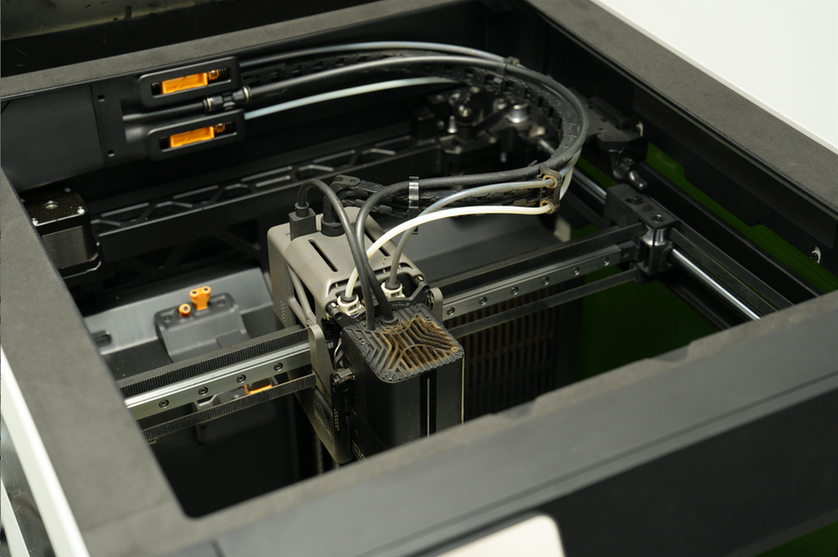

That’s where the brand-new H2D comes in. As the latest Bambu flagship, the H2D has a lot of what the community has been asking for: a dual extruder, a larger print volume, closed-loop servo motors, active chamber heating, and so much more.

However, Bambu couldn’t leave well enough alone with the H2D. Instead of just making a great 3D printer, which it no doubt is, the company decided to make a jack-of-all-trades machine. The H2D not only does 3D printing but also laser engraving, vinyl and paper cutting, and pen plotting. Yes, all of that is in one machine.

Laser Engraving Generates Lots of Soot, Smells, and Debris

If you’ve never done laser engraving or cutting before, there’s a lot of residue that comes along with it. I’ve been running laser engravers and cutters for over two years now, and the amount of dust, dirt, debris, and just grime that builds up from engraving certain materials is pretty nasty.

There’s also a crazy amount of smell (and fumes) that come with laser engraving. Lasers are essentially evaporating the material that’s being engraved, which can sometimes result in some pretty toxic fumes being generated.

Add the fumes to the soot that’s generated, and you’ll have a machine that both stinks and needs to be cleaned often. My laser engravers smell like the material I engrave for weeks or months afterward. I have some machines that are only used during craft fair season, and even after several months, I can still smell the residue inside.

Here’s where I think this will lead to with 3D printing: frequent cleaning of a machine and potentially smelly prints.

Bambu is already prepping for this, as they have a maintenance page for the H2D showing what just 40 hours of laser engraving looks like on the machine. That might sound like a long time, but I’ve done many engraves or cuts that lasted well over an hour by itself. Do a few of those a day or a few a week, and you’ll be at that stage in no time.

The problem is that even at five to ten hours of laser engraving/cutting, you’ll have a lot of soot and debris to clean up. If you’re like me, then you only maintenance your 3D printers when it’s required, not ahead of time. This would just make it so you have to maintenance the 3D printers much more often.

If You Want to Start Laser Engraving, Get a Dedicated Machine

While the all-in-one design could be nice for more budget-focused systems, the H2D should just stick to what it’s good at: 3D printing. The extra cost of adding the full 40W combo is $1,300.

To put that into comparison, for $1,600, so $300 more, the WeCreat Vision 40W is a great buy. It’s only a little more, but it gives you a larger working area than the H2D, is supported by Lightburn (industry-leading laser engraving software), and is a machine specifically designed for laser engraving.

Having a dedicated laser engraver also means that you can both 3D print and laser engrave at the same time. There’s no downtime while switching the machine from one function over to the other, you don’t have to worry about cleanup, and it’s there, always ready to work.

Having one machine that does it all might seem nice up front, but take it from me, you’ll want to separate them before long. I tried to convert my CNC router into a laser engraver so I could have one machine do both tasks. That lasted about two weeks before I determined I needed a separate machine.

The headache of converting the CNC into a laser, then having it be tied up while longer jobs ran, was just a hassle. The H2D will be no different. Add converting the 3D printer into a laser to having to clean it frequently, and you have a recipe for frustration.

WeCreat Vision 40W

$1599.99 $2199.99 Save

$600

The WeCreat Vision 40W is an at-home laser engraver and cutter. With 40W of power, it’s capable of cutting through up to 1/4 inch thick materials with ease. It also supports rotary engraving, as well as offering automated air assist. With a unique auto-lifting top, the autofocus is simple and easy to use, requiring no calibration. It has a work area of 15.75 by 10.63 inches, making it great for a wide range of projects.

If you want to do 3D printing and laser engraving, just buy the two machines separately. You’ll have more options (like a 20W, instead of only 10W or 40W, as Bambu offers), and being able to run two jobs at a time will prove itself invaluable as you enjoy both hobbies simultaneously.