Sublimation has long been touted as one of the best ways to get into making t-shirts and other personalized goods at home. While it’s a great technology, there are a lot of limitations. Recently, DTF (direct to film) printing has been picking up in popularity for hobbyists. Which tech should you have in your craft room?

What Is Sublimation?

Sublimation is a process in which polyester (or any poly-based material, like acrylic, etc.) is dyed by heating an ink, which turns into a gas. Essentially, you print sublimation ink onto sublimation paper, put it on a poly-based item, and heat press it. The heat converts the ink into a gas and that gas dyes the poly those colors. Typically, it takes about 60-90 seconds and around 400 degrees Fahrenheit for sublimation, sometimes called dye-sublimation, to transfer. If you try to sublimate something that isn’t poly-based, the colors will still transfer but not be as vibrant and likely wash out as they have no binding agent to keep them there.

What Is DTF?

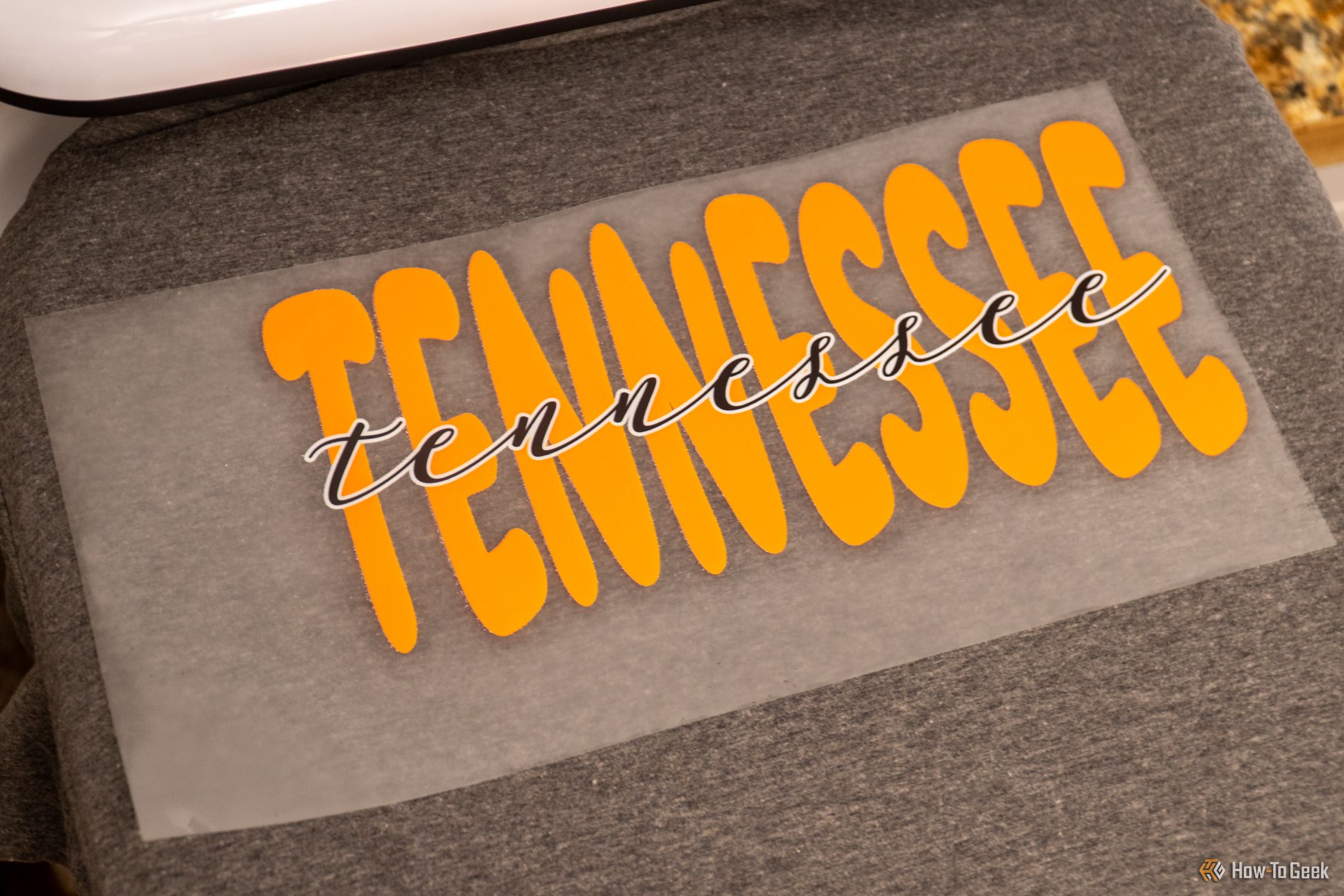

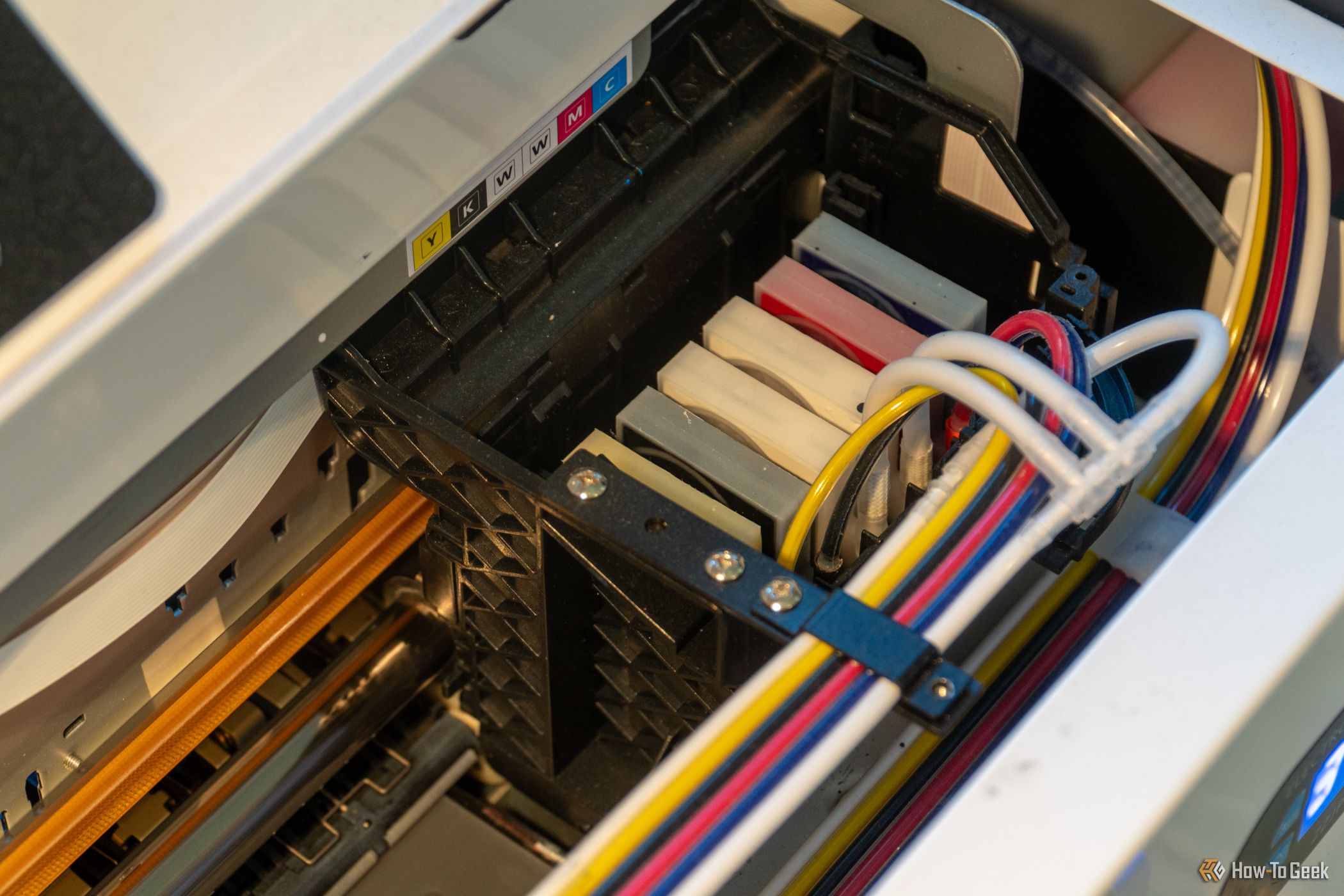

DTF, or direct to film, is a process in which a transfer is printed on plastic film, an adhesive is cured to the ink, and then the transfer is heat pressed onto a shirt. The printer lays down a full-color transfer and then a white backer on the image. Once printed, the ink cures for a few minutes, and then a TPU adhesive powder is applied and cured to the ink in a curing oven. At this point, the transfer is ready to press onto whatever item you’d like to use, be that a t-shirt (any fabric), wood, acrylic, or anything else. Typically, pressing a DTF transfer happens at around 10–15 seconds at 300-325 degrees Fahrenheit.

Advantages of Sublimation Printing

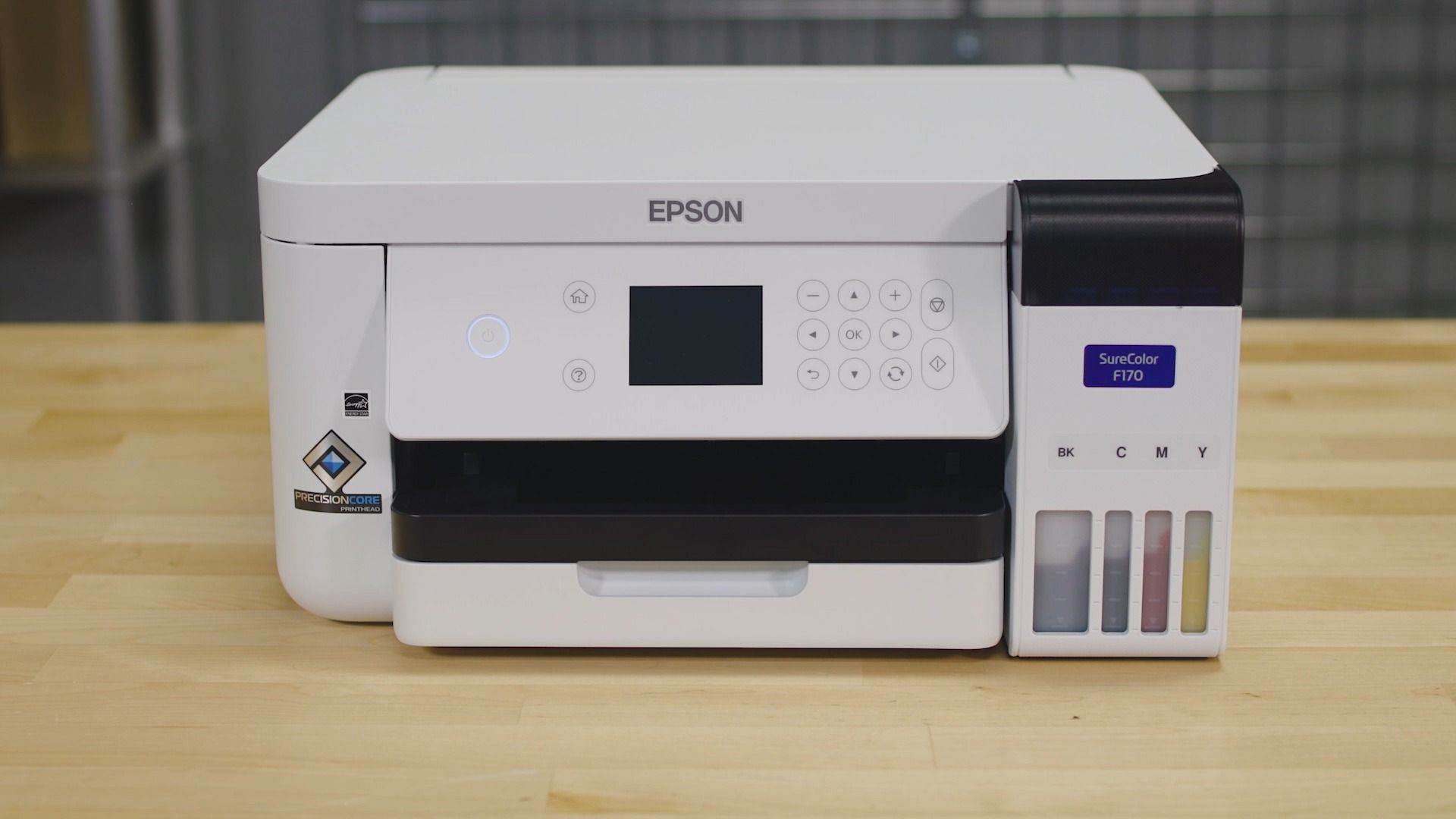

Sublimation has a few advantages that make it a great choice for certain crafts. Since the process dyes the material, sublimation sinks into whatever you press it on like it’s not even there. You’ll see the transfer but not feel it as it changes the actual colors of the garment, acrylic, or whatever you press it onto. There are also no adhesives, powder, or curing needed. Simply print, then press the transfer. You’ll also find that sublimation printers require little maintenance so long as you print with them every now and then. The inks flow fairly freely, and those doing low-volume designing and printing typically only once every few weeks or so.

Because of how sublimation is applied to items, it’s also the perfect at-home method to print full color on odd shapes. You can sublimate on acrylic, for example, and the ink will transfer only where the acrylic is. This makes it ideal for custom Christmas ornaments, key chains, and other oddly shaped items where the graphic would go edge-to-edge on an item.

Advantages of DTF Printing

While sublimation only works on poly-based items, DTF transfers apply to just about anything. This is thanks to the TPU adhesive that’s cured onto the ink before pressing, as the adhesive is what holds the transfer in place on whatever it’s pressed onto. This allows you to customize a wide range of items, from wood signs to 100% cotton t-shirts, leather, and more. Another big advantage to DTF printing is that DTF printers have white ink, and not just normal CMYK. This allows you to print full (and vibrant) colors on all fabrics, including darker apparel colors. DTF is also great for one-off print jobs, similar to sublimation because you can print a single graphic and then press it.

Disadvantages to Sublimation

Sublimation is only compatible with a very limited number of materials, basically anything that is polyester or poly-based. This means that if you want to transfer onto cotton, you’ll need something else to press into (like sublimatable vinyl). If you want to press onto wood, it’ll need some form of an acrylic/polycrylic coating to properly take the ink in.

Another disadvantage is that sublimation doesn’t print white. This means that if you want to sublimate on a colored garment, you basically have to stick to printing black. And, if you want to do full color on anything but white, you’ll need to put a white sublimatable vinyl on the fabric that you sublimate onto. This limits the designs you can do and means that there are extra steps required if you want white elements in a design or full color on anything but a white shirt. Think of it like a standard printer. If you put blue paper through your normal printer, the colors are printed washed out and with a blue hue. Sublimation will do the same if you try to press a design onto a blue shirt.

One other thing that sublimation can have an issue with is called “ghosting.” Ghosting is when the transfer is still hot, and the item moves under the heat press. I’ve had this happen when making some shirts before. When I pulled the item out and went to grab the transfer off, I slightly shifted it when it was still hot, and you could see that on the end result shirt.

Disadvantages of DTF Printing

The main disadvantage to DTF printing is the maintenance. You really need to run ink through the printhead at least twice a day. Personally, I run a head cleaning cycle in the morning when I walk into the office for the first time and when I leave the office at the end of the day/night. I do this even if I print throughout the day. The only time I don’t is if I’m printing late into the evening/night, and I had the ink flowing doing a normal print at the time I would typically be running the head cleaning.

Another downside to DTF is that it doesn’t apply to odd-shaped objects well. I used to run a sublimation printer but retired it and got rid of it when I moved to DTF. I tried applying DTF to a Christmas ornament that I cut on my laser, but since the graphic went off the edge, it tried to peel up. And the hole for the string wasn’t cut out anymore as the transfer is one big sheet basically. The only way to make ornaments that way would be to print a whole sheet of something, press it onto the material, and then laser cut it after the fact. Meanwhile, sublimation could easily be applied to pre-cut ornaments because of how the technology works.

Since the transfer is one big sheet, if you have a lot of solid color in a graphic, then the transfer will feel a little plastic-y or vinyl-y once it’s pressed. A good transfer, when pressed twice with proper heat and pressure, should sink into the fabric some. However, if you have a full graphic that has no holes in it at all, you’ll still feel the transfer no matter what due to how DTF printing works.

It’s for this reason that many DTF transfers use something called color knockout, where you remove a single color from an image (like black if you’re pressing on a black shirt, white on a white shirt, etc.). This “lightens” the graphic to make it not quite as thick since there’s less area where you’re laying down ink, and makes the graphic more breathable.

Which Tech Should You Use?

How-To Geek logo printed in full color with white on a DTF printer

Now that I’ve covered the pros and cons for both a sublimation and DTF printer…which should you choose? I’d say it really depends. Are you primarily working with white or lighter-colored polyester-based fabrics, and you don’t mind being limited to just those items? Well, sublimation gives a much cleaner press on those and truly sinks into the material for a polished finish. Sublimation is easier to use, requires less maintenance, and is great for odd-shaped items.

However, DTF rules the roost when it comes to putting graphics on 100% cotton shirts (something sublimation isn’t capable of at all) and printing white. It’s also great for its added versatility of things that the transfer can adhere to. However, it still requires a lot more maintenance than sublimation.

At the end of the day, my main recommendation, if you can swing the price, is a DTF printer. For all its drawbacks, the pros outweigh the cons, at least for me. Sublimation is great for what it works with, but since that list is so much more limited, it just didn’t have a place for long in my craft space. However, given the cost of a DTF printer (entry-level kits cost a few thousand dollars), sublimation is a much lower-cost hobby to get started with. If you’re not sure whether you want to decorate apparel or do custom stuff like that, sublimation will get you started for way cheaper. Plus, the third-party market is much more saturated; it’s fairly easy to find a used sublimation printer that doesn’t need any work on Facebook Marketplace.