Key Takeaways

- Injection molding offers a better finish than FDM printing models.

- Cleaning and supporting 3D printed model kits can be time-consuming.

- 3D printing technology has a place in the modeling hobby.

3D printing has allowed owners of these wonderful machines to create all sorts of amazing models. WIth the right finishing and painting, you can make something pretty amazing. However, can a 3D printer fill the same gap as injection-molded plastic model kits? Not quite yet, if you ask me.

Injection Molding Has a Better Finish Than FDM

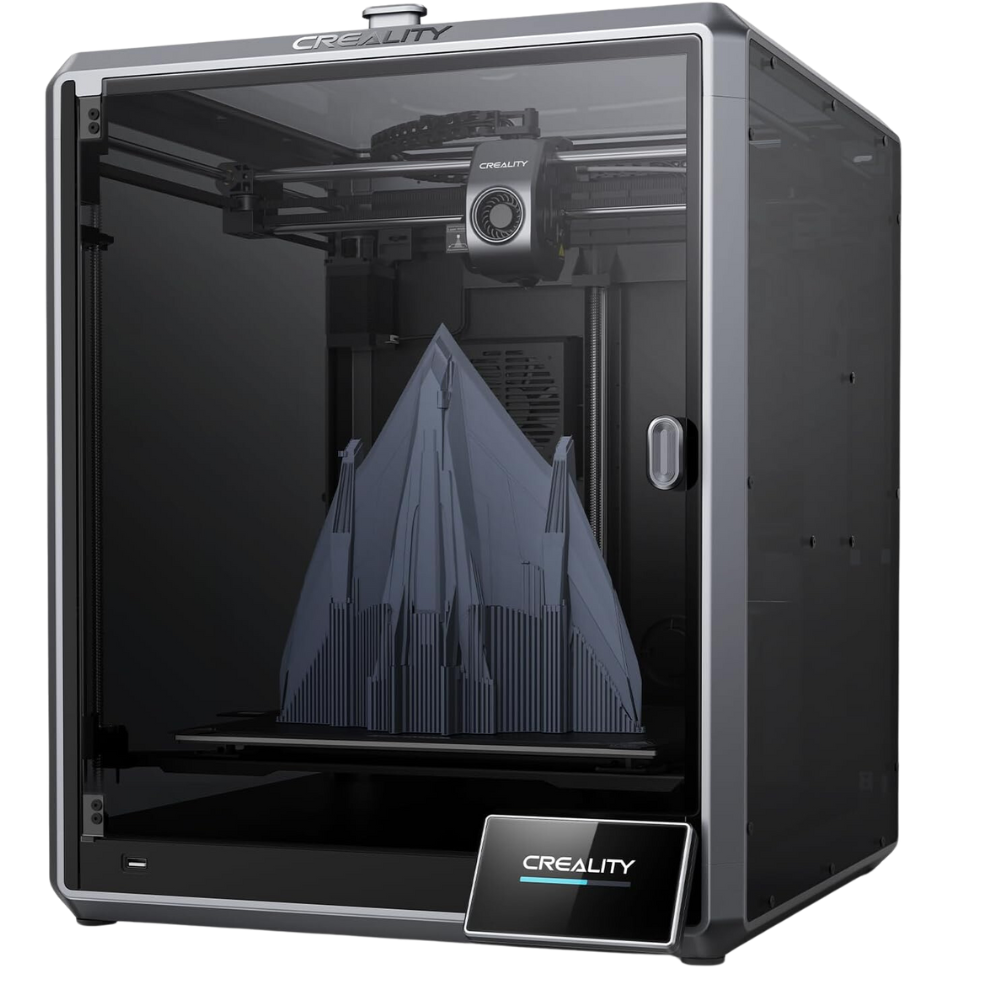

I currently use a Creality K1 Max for my printing needs, and like most modern FDM (Fused Deposition Modeling) printers, it can print in very thin layers that you won’t spot at a glance. However, at the scale and detail level of plastic model kits, you’re spending a lot of time sanding down the flat surfaces of your kit parts.

Creality K1 Max

The Creality K1 Max is a large volume consumer 3D printer with a high-speed Core XY design, and advanced AI-based automation systems.

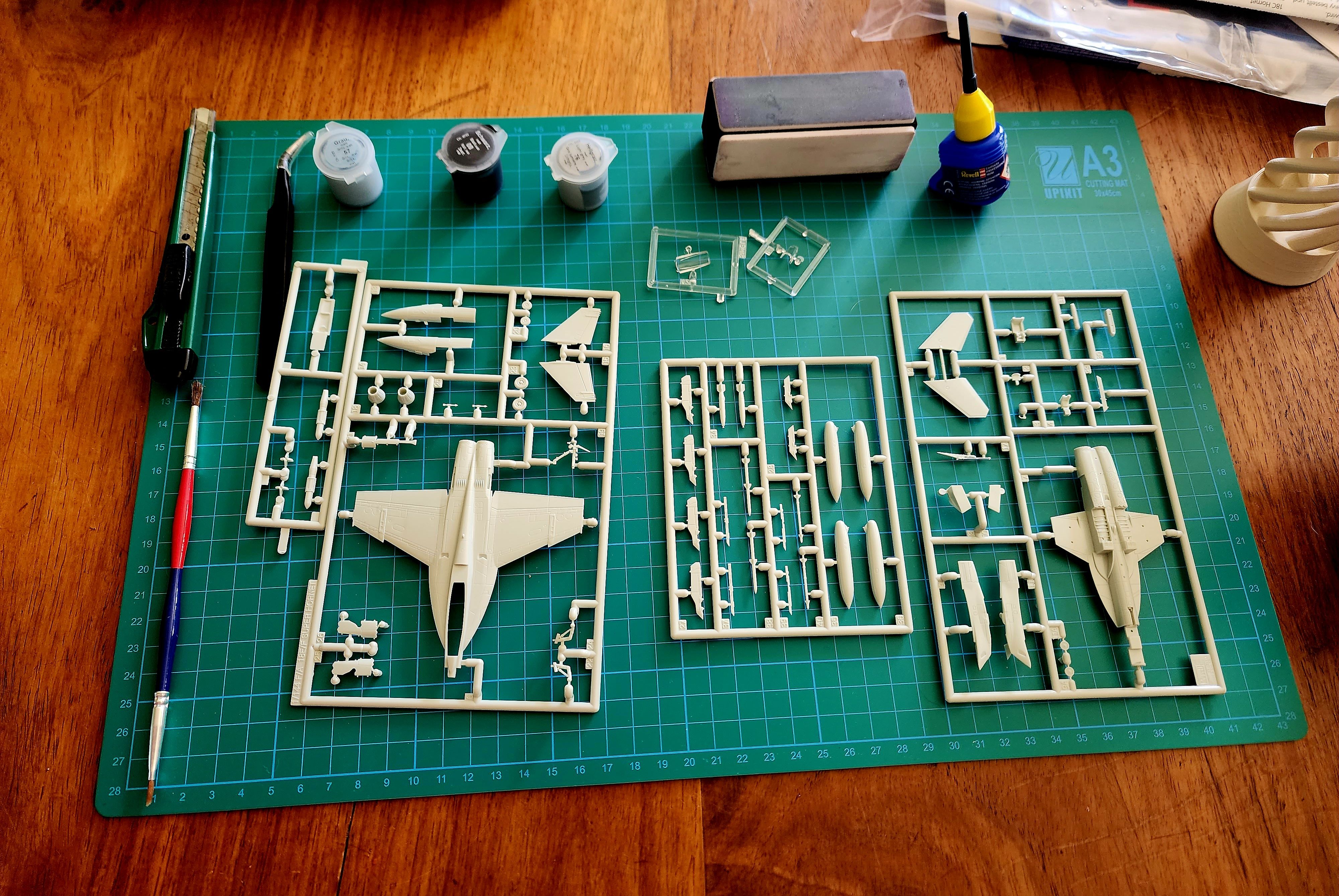

This is one of the major advantages of injection molding. Apart from the sprue marks, that you have to cut and sand a little, the finish of the molded parts is smooth and ready to paint without further finishing work.

Printed Kits Are a Pain To Support and Clean

One advantage of 3D printing model kit parts is that there is no sprue, and you can just print them loose on the bed. The downside is that many parts will need supports to print successfully, and so there’s a good chance that you’ll be spending a lot of time removing supports and working on removing their marks on the model pieces.

Of course, for kits that have been designed for printing, individual parts are often designed to minimize the need for supports, or hide where their marks are. However, you’re not going to get the clean and simple experience of snipping parts off a sprue.

Commercial Kit R&D Is Next-Level

Companies like Tamiya or Airfix spend a huge amount of money engineering their model kits. Creating an injection-mold die is extremely expensive, and they have to get it right. So there are months or years of design and testing before kits go into production.

Good kits will stay in production for decades. There are kits that are still unchanged from the 1970s and 1980s, because there’s nothing to improve. At least not to the extent where it would justify making new dies. So, when you buy a commercial model kit from a reputable brand, you’re almost certainly going to get something that fits together well and is a pleasure to build.

Obviously, CAD designs made by hobbyists. aren’t going to be up to the same standards most of the time, and you’ll have to tinker or modify things more than you’d typically do with commercial model kits.

Then again, the main selling point of 3D printing as a technology is that you can iterate designs quickly, and there’s nothing stopping you from improving a model kit made by someone else and passing the improvements on for more crowd-sourced design work. This is all great, but it’s probably not what most model kit buyers are looking for.

But, Why Not Just Print a Complete Model?

3D-printed model kit designs are getting better, and so are 3D printers, but the real reason I’m a little bemused by their existence is that the technology itself makes the idea of reproducing the model kit concept a little redundant.

Plastic model kits work the way they do because of manufacturing limitations. It’s the only way to offer an affordable plastic model at these detail levels, which modelers can then paint using hours of their labor, instead of paying for that labor.

I understand that much of the pleasure of making plastic model kits comes from gluing the parts together, but with a 3D printer you can do most or all of that virtually, and simply print the complete model out for painting. At the very least, depending on the design, you can reduce the total number of parts drastically. That’s before we get into the world of 3D resin printing, where the amount of complexity and detail that’s possible is mind-boggling.

That aside, take this FDM print of a mech file I found online.

I’m going to paint this model soon, and it all came out as one piece, using tree style supports to avoid marking up the piece. You could have done this as a model kit, but with the power of CAD and 3D printing, you can skip pretty much the whole thing.

In truth, 3D printing and model-making as a hobby will always be intertwined, but I see it more as a way for traditional kit builders to augment what they do (e.g. printing some more detailed parts to modify cheaper kits) or to make models that aren’t financially viable to do as a traditional kit.

3D printing will keep improving, and I have no doubt that at some point printed models will surpass what is feasible with injection-molded kits, but for now the two approached to model making are on almost separate tracks.