Anycubic is back once again with the new Kobra Plus, an interesting 3D printer that fills in the ever-shrinking gaps in Anycubic’s lineup. At the top end is the Kobra Max, a 400mm x 400mm x 450mm behemoth, while the other end has the Kobra, a smaller 220mm x 220mm x 250mm workhorse with a direct drive hotend setup for crunching through filaments, and now there is the Kobra Plus. At 300mm x 300mm x 350mm, it’s big enough to print helmets in one go like the Kobra Max, without needing a dedicated desk to itself.

With a higher flow volcano hotend, state-of-the-art automatic bed leveling, a large 4.3-inch touchscreen, filament runout sensor, and a large, thermally stable build plate, the Kobra Plus looks to be a great printer for a lot of people, but without the extra space and financial considerations of large-format machines like its older sibling, the Kobra Max. As long as you are okay with larger prints taking a longer amount of time, the Kobra Plus should definitely be on your list.

Pricing and availability

The Kobra Plus is coming in at a not-inexpensive $499; however, the first 2,000 customers who order from Anycubic’s own website can get $100 off retail and get this machine for just $399. You can buy it on Amazon as well as on Anycubic’s own website, and while Prime shipping is a great thing to have, being able to buy the printer, multiple rolls of Anycubic’s filament or spare parts all from one resource and ship in a single place is convenient.

What you’ll like

Anycubic touts the Kobra Plus as being able to print at up to 100mm/s and when paired with the dual-Z axis leadscrews and the dual 6000 RPM blower fans on the hotend for part cooling, that’s entirely doable. The default Cura slicing profile on the SD card actually runs the printer at 80mm/s print speed and 100mm/s travel speed; however, in my testing, I was able to increase travel moves up to 200mm/s. I ran the infill on prints at 120mm/s, and most print moves at around 75-90mm/s, and the Kobra Plus was able to keep up effortlessly.

The geared extruder with dual-drive feed gears works as flawlessly here as it did on the Kobra Max and the original Bondtech design on which is it based. A spring-tensioned lever arm allows you to feed in filament without much fuss or effort. One of the nicer things is that in the setup manual, Anycubic tells you how far to screw the screw in on the extruder for PLA, the more common filament, a very nice touch for new people who might not understand extruder tension. The 300mm x 300mm aluminum bed is covered with a large piece of borosilicate glass with a silicon carbide coating (Anycubic call it Carborundum). This coating gives the glass a slightly rough texture, and when it is heated, the coating becomes sticky to polymers and expands. Once you are done printing and the bed cools down, that texture shrinks and becomes less sticky making the part self-release.

(opens in new tab)

To interface with Marlin, Anycubic has designed a touch user interface for the 4.3-inch screen on the front right of the printer. This UI has a high contrast of white, black, and dark blue, and large clickable icons — even my chubby digits can click on things without too much precision and not worry about it. For slicing software, Anycubic recommends using Cura, and on the included SD card are some profiles for PLA and TPU that you can import into the latest version of Cura to have machine print settings for 0.2mm layer heights already there. However, you do not need to use Cura, as the Kobra Plus reads standard Gcode, you can use PrusaSlicer, IdeaMaker, Simplify3D, Kiri:Moto, or whatever other slicers you like to use that export Gcode. You will need to make your own machine profile, so maybe start with Cura and branch out if you feel you want or need more control or a different workflow.

| Specs | Anycubic Kobra Plus |

|---|---|

| Build volume | 300mm x 300mm x 350mm |

| Print surface | Carborundum-coated borosilicate glass |

| Extruder | 3:1 geared dual drive |

| Hotend | E3D Volcano style |

| Nozzle | 0.4mm Volcano (+1 spare) |

| Interface | 4.3-inch touchscreen, microSD Card, USB-B |

What you won’t like

While I would have preferred a magnetic spring steel sheet with a PEI coating, much like with the Vyper or the Kobra, the inclusion of a glass bed is understandable when you consider the size of the bed and the potential for warping. However, the LevIQ bed leveling should be able to even out any warping, and a flex plate would be significantly lighter than the glass, allowing you to potentially print even faster, plus it would have the benefit of heating up and cooling down faster.

The Kobra Plus runs a version of Marlin as its firmware; however, Anycubic has not at this time released a source file, which is against the rules of the GPL v3 license that Marlin is released under. We hope Anycubic supports the license and releases it soon, though given they haven’t for the Kobra and Kobra Max just yet, I wouldn’t get my hopes too high.

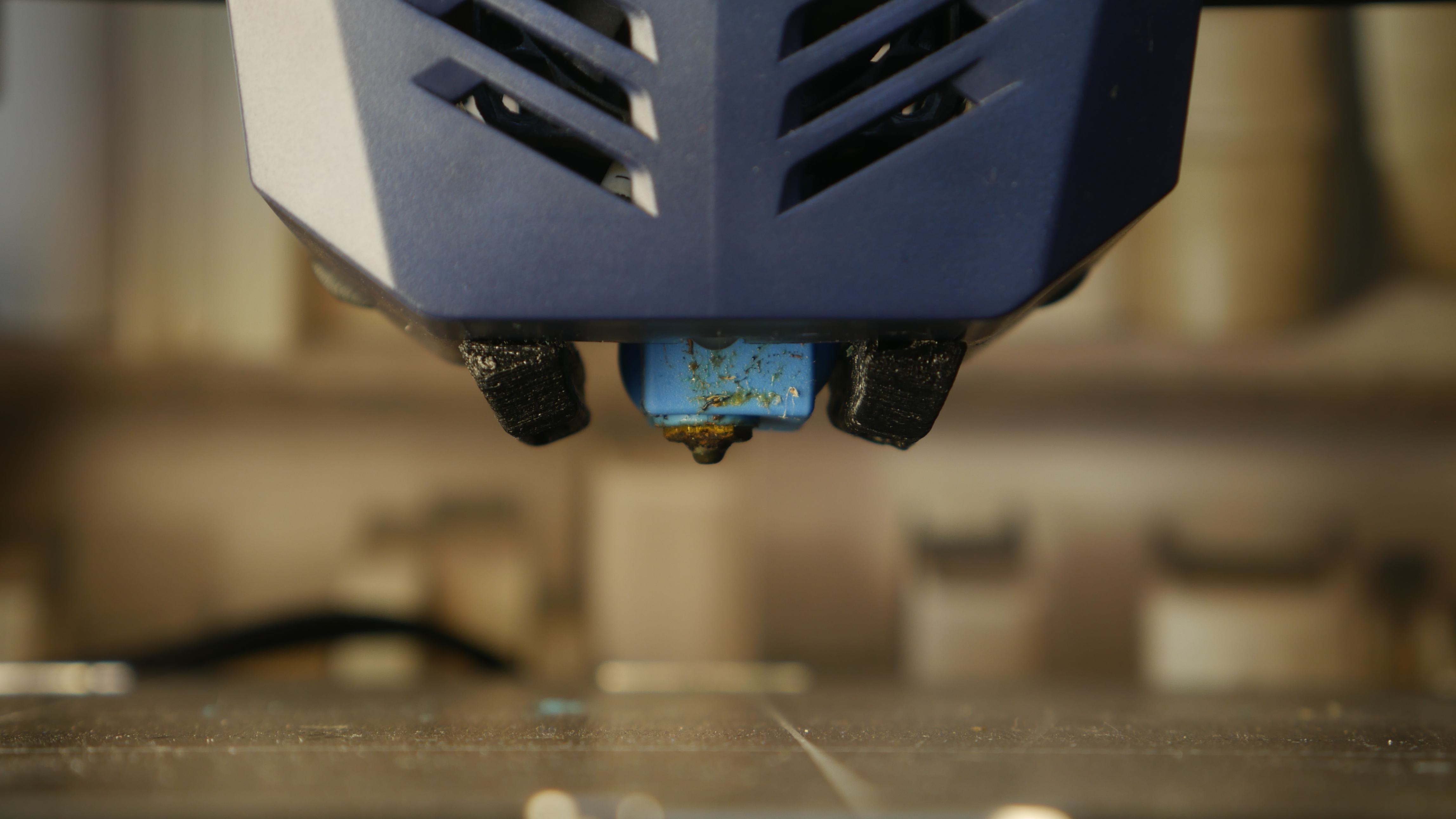

Some niggles I have with the printer are with the printhead, specifically the nozzle size and the fans. Anycubic proudly claims that its using two 6,000 RPM fans for print cooling on the Kobra Plus, the same as with the Kobra Max, but the problem, as with the Kobra Max, is that there are no fan ducts on the print head, it just blows down, with no direction to the model or the nozzle tip at all. I printed a set of fan ducts from the file repository website Thangs from user “Mandic Really” and these helped a lot, but I shouldn’t have to print something that should already be on the printer.

Similarly, the nozzle on the Kobra Plus, much like with the Kobra Max, is a 0.4mm brass volcano nozzle. This is the wrong choice. On a printer this large with a higher flow hotend like the Volcano, it should be a 0.6mm nozzle at the minimum, which can retain high detail but have a 50% larger bore for more flow, leading to prints taking less time and being stronger. I also think the material is incorrect, brass is a good material, but a nickel-plated copper nozzle would be better. It has a significantly better thermal conductivity, so it gets to temperature faster but also is more stable with that temperature, with the nickel plating acting as a non-stick coating so it’s easier to remove the filament ooze at the end of the print.

Competition

Unlike the Kobra Max, there are a fair few competitors in the size and price range, whether that be the Creality Ender 3 S1-Plus with its 300mm x 300mm x 300mm build volume, an all-metal direct drive “Sprite” extruder, a CR-Touch for automatic bed leveling and the 4.3-inch touchscreen for $529. Or the SV03 from Sovol, with its 350mm x 350mm x 400mm build volume, direct-drive Titan style extruder and a legit BL-Touch for its automatic bed leveling and filament run out for $459, or the Artillery Sidewinder X2 from Artillery, which has a 300mm x 300mm x 400mm build volume, a titan style direct-drive extruder and an AC heated bed for rapid heat-up times and stable heating across the entirety of the bed for $469. Anycubic isn’t alone here, but surprisingly, I think Anycubic is coming out close to being on top.

Should you buy it?

You should buy this if …

- You want a large format printer in a relatively small footprint

- You print a lot of large items

- You don’t mind using a lot of filament

- You don’t mind waiting a long time for prints

You shouldn’t buy this if …

- Space is a strong constraint

- Electricity is very costly where you are

- You strictly adhere to open-source licenses and regulations

Not everyone is going to need a large-format 3D printer. They take up more space, consume more electricity, and consume significantly more filament, but if you do need a larger format 3D printer, the Kobra Plus is a great machine to get started with. Cosplayers are an ideal candidate to buy the Kobra Plus because you can fit full-sized helmets on it as well as large amor pieces without having to chop them up too much, or even at all. The filament run-out sensor is also pretty useful for that large, multi-day, potentially multiple rolls of filament prints. Having the printer recognize it has run out of filament, pause the print, move itself to safety, and beep at you to refill the filament is very useful when you are 96 hours into a helmet, trust me.

Anycubic has built a machine that has a decently large build volume, a higher flow hotend, a great interface, a well-built extruder and without a shadow of a doubt the best auto leveling system of all the printers I mentioned before. It is more expensive than all of them at $499, but it is not an exorbitant amount and is more than reasonably priced in my opinion.

Anycubic also has a well-stocked inventory of spares for their printer on their website in case you were to break the large glass bed, the heated bed, or the hotend itself. Those are all available for reasonable prices, and you know they are going to work as they are direct from the manufacturer.

(opens in new tab)

Anycubic’s Kobra Plus is a larger format 3D printer that is capable of getting some serious prints done.